Small business inventory management systems are essential tools for businesses of all sizes, providing a comprehensive solution for tracking, controlling, and optimizing inventory levels. With these systems, small businesses can streamline their operations, reduce costs, and improve customer satisfaction.

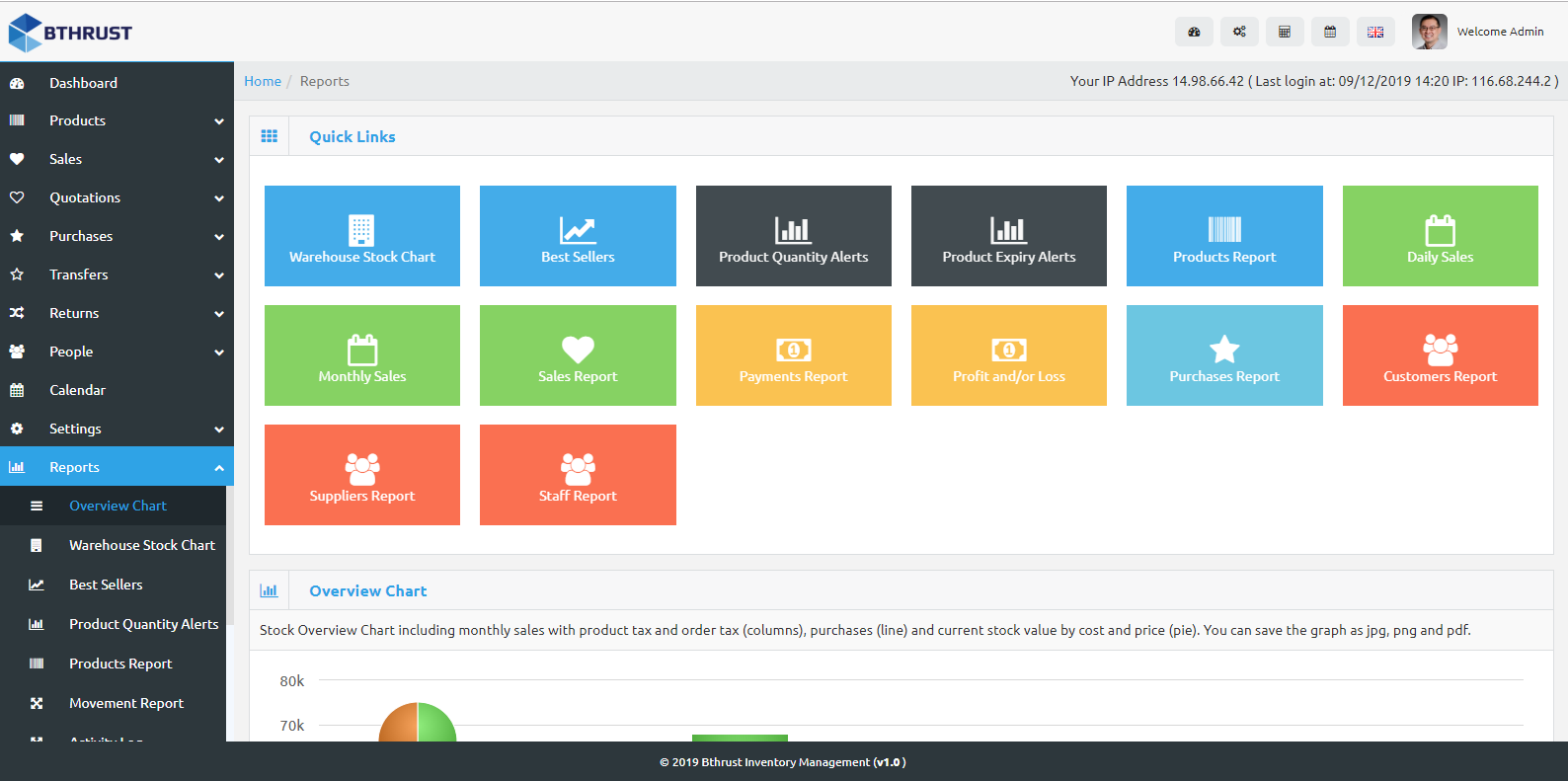

Inventory management software offers a wide range of features tailored to the specific needs of small businesses, including real-time inventory tracking, automated reordering, and detailed reporting.

Inventory Management Software Features

Inventory management software is a valuable tool for small businesses. It can help you track your inventory levels, manage your orders, and optimize your supply chain. As a result, you can save time and money, and improve your customer service.

Essential Features

When choosing inventory management software, there are a few essential features to look for:

- Inventory tracking:The software should allow you to track your inventory levels in real time. This will help you avoid overstocking or understocking.

- Order management:The software should allow you to manage your orders from start to finish. This includes processing orders, tracking shipments, and managing returns.

- Supplier management:The software should allow you to manage your suppliers. This includes tracking their performance, placing orders, and managing payments.

- Reporting:The software should provide you with reports on your inventory levels, orders, and suppliers. This information can help you make informed decisions about your business.

Benefits of Using Inventory Management Software

There are many benefits to using inventory management software. Some of the most notable benefits include:

- Reduced costs:Inventory management software can help you reduce your costs by optimizing your supply chain and reducing waste.

- Improved customer service:Inventory management software can help you improve your customer service by ensuring that you always have the products that your customers want in stock.

- Increased efficiency:Inventory management software can help you increase your efficiency by automating many of the tasks that are involved in inventory management.

Examples of Inventory Management Software

There are many different inventory management software solutions available. Some of the most popular options include:

- QuickBooks Inventory Manager:QuickBooks Inventory Manager is a popular option for small businesses. It is easy to use and affordable.

- NetSuite Inventory Management:NetSuite Inventory Management is a more comprehensive option that is suitable for larger businesses. It offers a wide range of features, including inventory tracking, order management, and supplier management.

- Fishbowl Inventory:Fishbowl Inventory is a cloud-based inventory management solution that is designed for small businesses. It is easy to use and offers a wide range of features.

Inventory Tracking and Control

Inventory tracking and control are essential for any small business that wants to manage its inventory efficiently and avoid stockouts or overstocking. There are a number of different methods that can be used to track and control inventory levels, and the best method for a particular business will depend on its size, the type of inventory it carries, and its budget.

One common method of inventory tracking is to use a manual system, such as a spreadsheet or a physical inventory tag system. Manual systems are relatively simple to set up and use, but they can be time-consuming and error-prone. Another option is to use an automated inventory tracking system, such as a barcode scanner or a radio frequency identification (RFID) system.

Automated systems are more expensive than manual systems, but they can be more efficient and accurate.

Setting Up an Inventory Tracking System

Once a business has decided on a method of inventory tracking, it needs to set up a system to track its inventory levels. This system should include the following elements:

- A list of all inventory items, including the item’s name, description, and quantity on hand.

- A system for tracking inventory transactions, such as purchases, sales, and adjustments.

- A system for generating inventory reports, such as inventory summaries and reorder reports.

Tips for Managing Inventory Levels Effectively

Once a business has set up an inventory tracking system, it needs to develop a strategy for managing its inventory levels effectively. This strategy should include the following elements:

- Establishing safety stock levels for each inventory item.

- Monitoring inventory levels regularly and placing orders for new inventory when necessary.

- Using inventory reports to identify trends and make adjustments to inventory levels as needed.

Inventory Optimization: Small Business Inventory Management Systems

For small businesses, inventory optimization is crucial to ensure efficient operations and profitability. By optimizing inventory levels, businesses can reduce costs, improve cash flow, and enhance customer satisfaction.

Inventory optimization involves techniques such as demand forecasting, safety stock management, and inventory turnover analysis. Demand forecasting helps businesses predict future demand based on historical data and market trends. Safety stock management ensures that businesses maintain adequate inventory levels to meet unexpected demand fluctuations.

Inventory turnover analysis helps businesses assess how efficiently they are managing their inventory and identify areas for improvement.

Benefits of Inventory Optimization, Small business inventory management systems

- Reduced storage costs: Optimized inventory levels reduce the need for excessive storage space, saving businesses money.

- Improved cash flow: By avoiding overstocking, businesses can free up cash flow for other operations.

- Increased customer satisfaction: Optimized inventory levels help businesses meet customer demand promptly, reducing the risk of stockouts and improving customer loyalty.

Inventory Forecasting

Inventory forecasting is the process of predicting future demand for inventory. This is a critical process for businesses of all sizes, as it helps them to ensure that they have the right amount of inventory on hand to meet customer demand without overstocking or understocking.

There are a number of different methods that can be used to forecast inventory demand. Some of the most common methods include:

- Historical data:This method uses historical sales data to predict future demand. The assumption is that past demand is a good indicator of future demand.

- Trend analysis:This method looks at trends in demand over time to predict future demand. The assumption is that demand will continue to follow the same trend in the future.

- Seasonal factors:This method takes into account seasonal fluctuations in demand. The assumption is that demand will be higher during certain times of the year than others.

- Causal factors:This method looks at the relationship between demand and other factors, such as economic conditions, marketing campaigns, and product launches. The assumption is that these factors will have an impact on future demand.

No single forecasting method is perfect. The best method for a particular business will depend on the nature of the business, the products it sells, and the availability of data.

Tips for Creating Accurate Inventory Forecasts

Here are a few tips for creating accurate inventory forecasts:

- Use multiple forecasting methods.No single forecasting method is perfect. By using multiple methods, you can get a more accurate picture of future demand.

- Consider all relevant factors.When forecasting demand, it is important to consider all of the factors that could affect demand, such as seasonality, economic conditions, and marketing campaigns.

- Monitor your forecasts.Inventory forecasts are not set in stone. They should be monitored regularly and adjusted as needed.

Benefits of Using Inventory Forecasting Software

Inventory forecasting software can help businesses to create more accurate inventory forecasts. This software can automate the forecasting process, which can save time and improve accuracy. Additionally, inventory forecasting software can provide businesses with insights into demand patterns, which can help them to make better decisions about inventory management.

Inventory Replenishment

Inventory replenishment involves managing inventory levels to ensure that the right amount of stock is available to meet customer demand while minimizing waste and storage costs. Several methods can be used for inventory replenishment, each with its advantages and disadvantages.

Factors to consider when choosing a replenishment method include the nature of the product, demand patterns, lead times, and storage space availability. Optimizing inventory replenishment involves finding the right balance between stock levels and customer service levels while minimizing costs.

Replenishment Methods

- Periodic Replenishment:Inventory is replenished at fixed intervals, regardless of demand. This method is simple to implement but can lead to overstocking or stockouts.

- Continuous Replenishment:Inventory is replenished continuously as demand occurs. This method requires real-time inventory tracking and can help prevent stockouts but may lead to higher storage costs.

- Just-in-Time (JIT) Replenishment:Inventory is replenished only when needed to meet immediate demand. This method minimizes inventory carrying costs but requires close coordination with suppliers and can be risky if demand is unpredictable.

- Minimum-Maximum Replenishment:Inventory is replenished when it reaches a predetermined minimum level. This method helps prevent stockouts but can lead to overstocking if demand is low.

- Two-Bin Replenishment:Inventory is divided into two bins. One bin is used to meet current demand, while the other is used to store safety stock. When the first bin is empty, the second bin is used to replenish it.

Tips for Optimizing Inventory Replenishment

- Use demand forecasting to predict future demand patterns.

- Monitor inventory levels regularly and adjust replenishment schedules as needed.

- Consider using safety stock to buffer against unexpected demand fluctuations.

- Automate inventory replenishment processes to reduce errors and improve efficiency.

- Collaborate with suppliers to ensure timely delivery and reduce lead times.

Inventory Reporting

Inventory reporting provides valuable insights into the management and optimization of your inventory. These reports offer a comprehensive overview of your inventory levels, helping you make informed decisions and streamline your operations.

There are several types of inventory reports available, each serving a specific purpose:

- Stock Status Report:Provides a snapshot of your current inventory levels, including the quantity on hand, allocated, and available for sale.

- Inventory Valuation Report:Shows the total value of your inventory, categorized by product, location, or other criteria.

- Inventory Turnover Report:Calculates the rate at which your inventory is sold and replaced, providing insights into the efficiency of your inventory management.

- Inventory Ageing Report:Indicates the age of your inventory, helping you identify slow-moving or obsolete items.

- ABC Analysis Report:Categorizes your inventory items based on their value and usage, allowing you to focus on managing the most critical items.

Benefits of Using Inventory Reports

- Improved Inventory Accuracy:Reports help you identify discrepancies and errors in your inventory records, ensuring accurate data for decision-making.

- Optimized Inventory Levels:By analyzing reports, you can determine optimal inventory levels to avoid overstocking or stockouts.

- Reduced Inventory Costs:Reports provide insights into inventory holding costs, allowing you to minimize unnecessary expenses.

- Improved Customer Service:Accurate inventory reporting ensures you have the right products in stock to meet customer demand.

- Enhanced Planning and Forecasting:Reports provide historical data and trends, enabling you to make informed predictions and plan for future inventory needs.

Tips for Creating and Using Inventory Reports Effectively

- Define Your Reporting Needs:Determine the specific information you need from your inventory reports.

- Use the Right Software:Choose inventory management software that provides the reporting capabilities you require.

- Set Up Regular Reporting:Establish a schedule for generating and reviewing inventory reports.

- Analyze the Data:Carefully examine the reports to identify trends, patterns, and areas for improvement.

- Make Data-Driven Decisions:Use the insights from your inventory reports to make informed decisions about inventory management.

Ultimate Conclusion

By implementing an effective inventory management system, small businesses can gain a competitive edge, improve their bottom line, and lay the foundation for future growth.

Q&A

What are the benefits of using inventory management software?

Inventory management software can help small businesses save time and money by automating tasks, reducing errors, and improving inventory accuracy.

How can I choose the right inventory management software for my business?

When choosing inventory management software, consider the size of your business, the types of products you sell, and your budget.

What are some tips for effective inventory management?

Some tips for effective inventory management include setting up a regular inventory schedule, using inventory management software, and training staff on inventory procedures.