Managing inventory for small businesses is a crucial aspect of ensuring efficient operations and maximizing profitability. Understanding the types of inventory, effective strategies, and challenges involved empowers small businesses to optimize their inventory management practices and drive success.

This comprehensive guide will delve into the intricacies of inventory management, providing actionable techniques, best practices, and software solutions to help small businesses navigate the complexities of inventory management.

Inventory Management Basics

Inventory management is the backbone of any small business. It ensures that you have the right products in stock to meet customer demand, while also minimizing the risk of overstocking and spoilage. There are many different types of inventory, each with its own unique impact on small businesses.

Raw Materials

Raw materials are the basic components used to create finished products. They can include everything from fabric to wood to metal. Managing raw materials effectively is essential for ensuring that you have the supplies you need to meet customer demand.

If you run out of raw materials, you will not be able to produce finished products, which can lead to lost sales and unhappy customers.

Work-in-Progress (WIP)

WIP is inventory that is in the process of being manufactured. It can include partially finished products, as well as products that are waiting to be assembled or packaged. Managing WIP effectively is essential for ensuring that you have a smooth and efficient production process.

If you have too much WIP, it can lead to bottlenecks and delays. If you have too little WIP, you may not be able to meet customer demand.

Finished Goods

Finished goods are products that are ready to be sold to customers. Managing finished goods effectively is essential for ensuring that you have the right products in stock to meet customer demand. If you have too much finished goods, you may be tying up valuable cash flow.

If you have too little finished goods, you may not be able to meet customer demand.

Inventory Management Techniques

Efficient inventory management is crucial for small businesses to maintain optimal stock levels, minimize waste, and maximize profits. Here are key techniques to consider:

Effective inventory management requires a combination of strategies to optimize stock levels and meet customer demand. These techniques include forecasting demand, setting appropriate inventory levels, and utilizing technology for automation and efficiency.

Forecasting Demand

Accurately forecasting demand is essential for determining the optimal inventory levels. Techniques include:

- Historical Data Analysis:Examine past sales patterns to identify trends and seasonality.

- Market Research:Conduct surveys, analyze industry reports, and monitor competitor activity to understand market dynamics.

- Time Series Analysis:Use statistical models to analyze historical data and predict future demand.

Setting Inventory Levels

Once demand is forecasted, businesses need to determine the appropriate inventory levels. Key considerations include:

- Safety Stock:Maintaining a buffer stock to cover unexpected fluctuations in demand or supply chain disruptions.

- Economic Order Quantity (EOQ):Calculating the optimal quantity to order at a time to minimize total inventory costs.

- Just-in-Time (JIT) Inventory:Keeping inventory levels as low as possible and replenishing stock only when needed.

Technology in Inventory Management

Technology plays a vital role in streamlining inventory management processes:

- Inventory Management Software:Centralized systems that track inventory levels, automate reordering, and provide real-time visibility.

- Radio Frequency Identification (RFID):Using RFID tags to track inventory items and automate inventory counting.

- Warehouse Management Systems (WMS):Comprehensive systems that manage warehouse operations, including inventory tracking, order fulfillment, and shipping.

Inventory Management Challenges

Small businesses face unique inventory management challenges that can impact their profitability and efficiency. These challenges include:

- Managing seasonality:Demand for products can fluctuate significantly depending on the time of year, making it difficult to maintain optimal inventory levels.

- Product obsolescence:Technology and consumer preferences change rapidly, leading to products becoming obsolete and unsaleable.

- Limited storage space:Small businesses often have limited storage space, which can make it difficult to accommodate large or bulky inventory.

- Cash flow constraints:Managing inventory can tie up significant amounts of cash, which can be a challenge for small businesses with limited financial resources.

- Lack of technology:Small businesses may not have the resources to invest in inventory management software or systems, which can make it difficult to track and manage inventory effectively.

Overcoming Inventory Management Challenges

Small businesses can overcome these challenges by implementing effective inventory management strategies. These strategies include:

- Forecasting demand:Using historical data and industry trends to predict future demand for products, which can help businesses maintain optimal inventory levels.

- Managing product lifecycles:Identifying products that are nearing obsolescence and implementing strategies to sell them before they become unsaleable.

- Optimizing storage space:Using vertical storage solutions, shelves, and other space-saving techniques to maximize storage capacity.

- Negotiating with suppliers:Establishing relationships with suppliers to negotiate favorable payment terms and discounts, which can help improve cash flow.

- Investing in technology:Implementing inventory management software or systems to automate inventory tracking, forecasting, and reporting, which can improve efficiency and accuracy.

Examples of Successful Inventory Management

Many small businesses have successfully addressed inventory management challenges by implementing effective strategies. For example:

- A small clothing store implemented a demand forecasting system that helped them predict seasonal demand for different products, reducing their inventory holding costs by 20%.

- A hardware store partnered with a supplier to offer a consignment program for slow-moving items, which allowed them to sell obsolete products without tying up cash.

- A restaurant implemented a just-in-time inventory system that allowed them to reduce their storage space requirements by 50% and improve their cash flow.

Inventory Management Best Practices

To ensure efficient and profitable inventory management in small businesses, adhering to a set of best practices is crucial. These practices cover various aspects of inventory management, including tracking, forecasting, and cost control.

By implementing these best practices, small businesses can streamline their inventory management processes, reduce waste, and improve overall profitability.

Inventory Tracking

Effective inventory tracking is the foundation of successful inventory management. It involves maintaining accurate and up-to-date records of all inventory items, including their quantities, locations, and statuses.

- Regular physical counts:Conducting regular physical counts of inventory helps identify discrepancies between physical stock and records, ensuring accuracy.

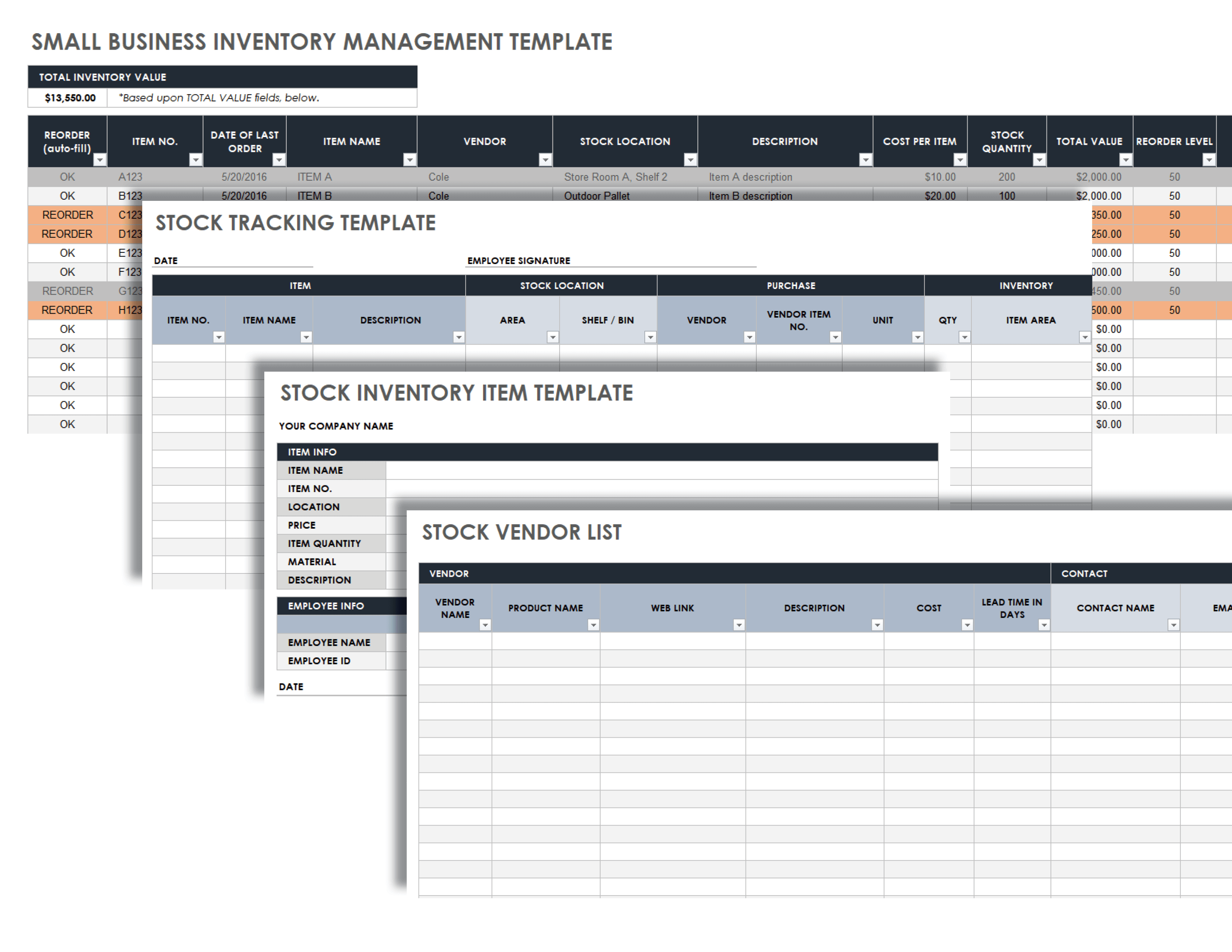

- Use of inventory management software:Utilizing inventory management software streamlines tracking processes, provides real-time visibility into inventory levels, and automates tasks like reordering.

Inventory Forecasting

Accurate inventory forecasting enables businesses to anticipate future demand and plan accordingly. This helps prevent overstocking or understocking, which can lead to lost sales or unnecessary costs.

- Historical data analysis:Analyzing historical sales data can provide valuable insights into demand patterns, helping businesses make informed forecasting decisions.

- Trend analysis:Monitoring industry trends and economic indicators can help businesses identify potential changes in demand and adjust their forecasts accordingly.

Cost Control

Managing inventory costs effectively is essential for maintaining profitability. Businesses should implement strategies to minimize costs while ensuring adequate inventory levels.

- Negotiating with suppliers:Negotiating favorable terms with suppliers, such as discounts or bulk pricing, can reduce procurement costs.

- Optimizing inventory levels:Maintaining optimal inventory levels, neither too high nor too low, minimizes holding costs and prevents spoilage or obsolescence.

Inventory Management Software: Managing Inventory For Small Business

Inventory management software can streamline your inventory processes, providing you with real-time visibility into your stock levels and helping you make informed decisions about ordering and storage.

There are many different inventory management software options available, each with its own set of features and benefits. To choose the right software for your business, you need to consider your specific needs and requirements.

Key Features to Consider

- Inventory tracking:The software should allow you to track your inventory levels in real time, so you always know what you have on hand.

- Reporting:The software should provide you with detailed reports on your inventory levels, sales, and other key metrics.

- Integrations:The software should integrate with your other business systems, such as your accounting software and your e-commerce platform.

Recommendations for Choosing the Right Software, Managing inventory for small business

When choosing inventory management software, it is important to consider the following factors:

- The size of your business:Small businesses will have different needs than large businesses, so it is important to choose software that is designed for your size.

- The type of inventory you manage:If you manage a large number of SKUs or a complex inventory, you will need software that is designed to handle your specific needs.

- Your budget:Inventory management software can range in price from free to thousands of dollars per month, so it is important to choose software that fits your budget.

By considering these factors, you can choose the right inventory management software for your business and improve your inventory management processes.

Closing Notes

By implementing effective inventory management strategies, small businesses can streamline their operations, reduce waste, and enhance profitability. Embracing technology, adopting best practices, and addressing challenges proactively empowers businesses to optimize their inventory management processes and achieve long-term success.

FAQ Corner

What are the key benefits of effective inventory management for small businesses?

Effective inventory management helps small businesses optimize stock levels, reduce waste, improve customer satisfaction, and maximize profits.

How can small businesses overcome inventory management challenges?

Small businesses can overcome inventory management challenges by implementing forecasting techniques, managing seasonality, minimizing product obsolescence, and leveraging technology.

What are some best practices for inventory management in small businesses?

Best practices for inventory management include regular inventory tracking, accurate forecasting, cost control measures, and utilizing inventory management software.