Inventory management system small business – Inventory management is a critical aspect of any business, but it can be especially challenging for small businesses with limited resources. An inventory management system (IMS) can help you streamline your inventory processes, reduce costs, and improve efficiency. In this guide, we’ll provide an overview of IMSs, discuss the different types available, and highlight the benefits of implementing one for your small business.

An IMS can help you track your inventory levels, manage orders, and generate reports. This can help you avoid overstocking or understocking, and ensure that you always have the products your customers need.

Overview of Inventory Management Systems for Small Businesses

Inventory management systems (IMS) are software solutions designed to help businesses track and manage their inventory levels. They provide real-time visibility into stock levels, allowing businesses to optimize their inventory and reduce costs.

For small businesses, inventory management is crucial for several reasons. It helps them:

- Prevent stockouts and lost sales

- Reduce inventory carrying costs

- Improve customer satisfaction

- Make better informed decisions about purchasing and production

Benefits of Inventory Management Systems

IMS offer a wide range of benefits for small businesses, including:

- Increased accuracy:IMS automate inventory tracking, reducing human error and improving the accuracy of inventory records.

- Improved efficiency:IMS streamline inventory management processes, saving time and effort for business owners.

- Enhanced visibility:IMS provide real-time visibility into inventory levels, allowing businesses to make informed decisions about their stock.

- Reduced costs:IMS help businesses reduce inventory carrying costs by optimizing stock levels and preventing overstocking.

- Improved customer service:IMS help businesses prevent stockouts and fulfill customer orders more efficiently, leading to improved customer satisfaction.

Types of Inventory Management Systems

For small businesses, selecting the right inventory management system is crucial. There are two primary types: manual and software-based systems.

Manual Inventory Management

Manual systems involve tracking inventory manually, often using spreadsheets or physical records. While this approach can be suitable for small businesses with limited inventory, it can become cumbersome and error-prone as the business grows.

Advantages:

- Low cost

- Easy to implement

Disadvantages:

- Time-consuming

- Prone to errors

- Limited reporting and analytics

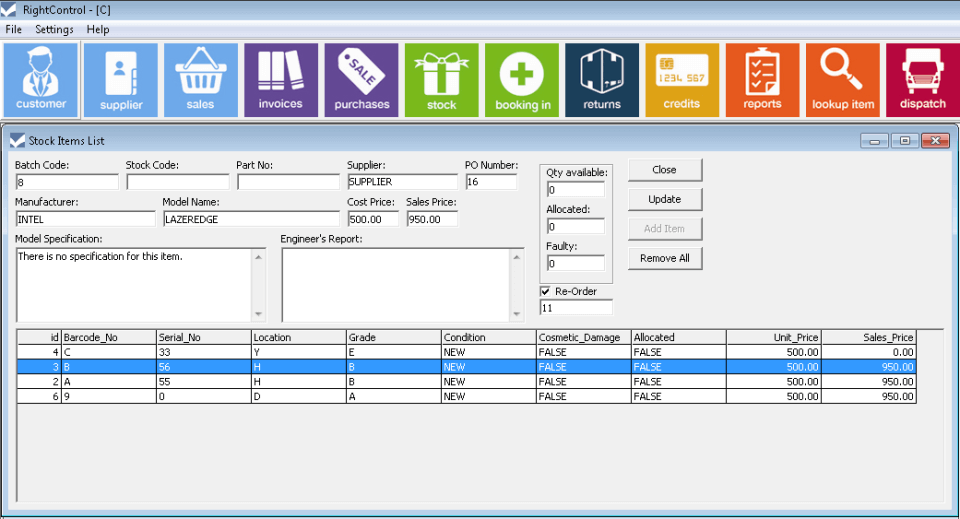

Software-Based Inventory Management

Software-based systems use specialized software to automate inventory tracking. They offer various features, including real-time updates, automated alerts, and advanced reporting.

Advantages:

- Saves time and effort

- Improves accuracy

- Provides insights through analytics

Disadvantages:

- Can be more expensive

- Requires training and setup

Features to Consider When Choosing an Inventory Management System

Choosing the right inventory management system for your small business is crucial for streamlining operations, reducing costs, and improving customer satisfaction. Here are some essential features to consider when making your decision:

An inventory management system can help you streamline your inventory management processes by providing you with real-time visibility into your inventory levels, automating tasks, and providing insights to make better decisions.

Essential Features

- Real-time inventory tracking:Keep track of your inventory levels in real time to avoid overstocking or stockouts.

- Automated inventory replenishment:Set up automatic reordering rules to ensure you always have the right amount of inventory on hand.

- Inventory forecasting:Forecast future demand based on historical data to optimize your inventory levels.

- Multi-location inventory management:Manage inventory across multiple locations to ensure optimal stock levels at each location.

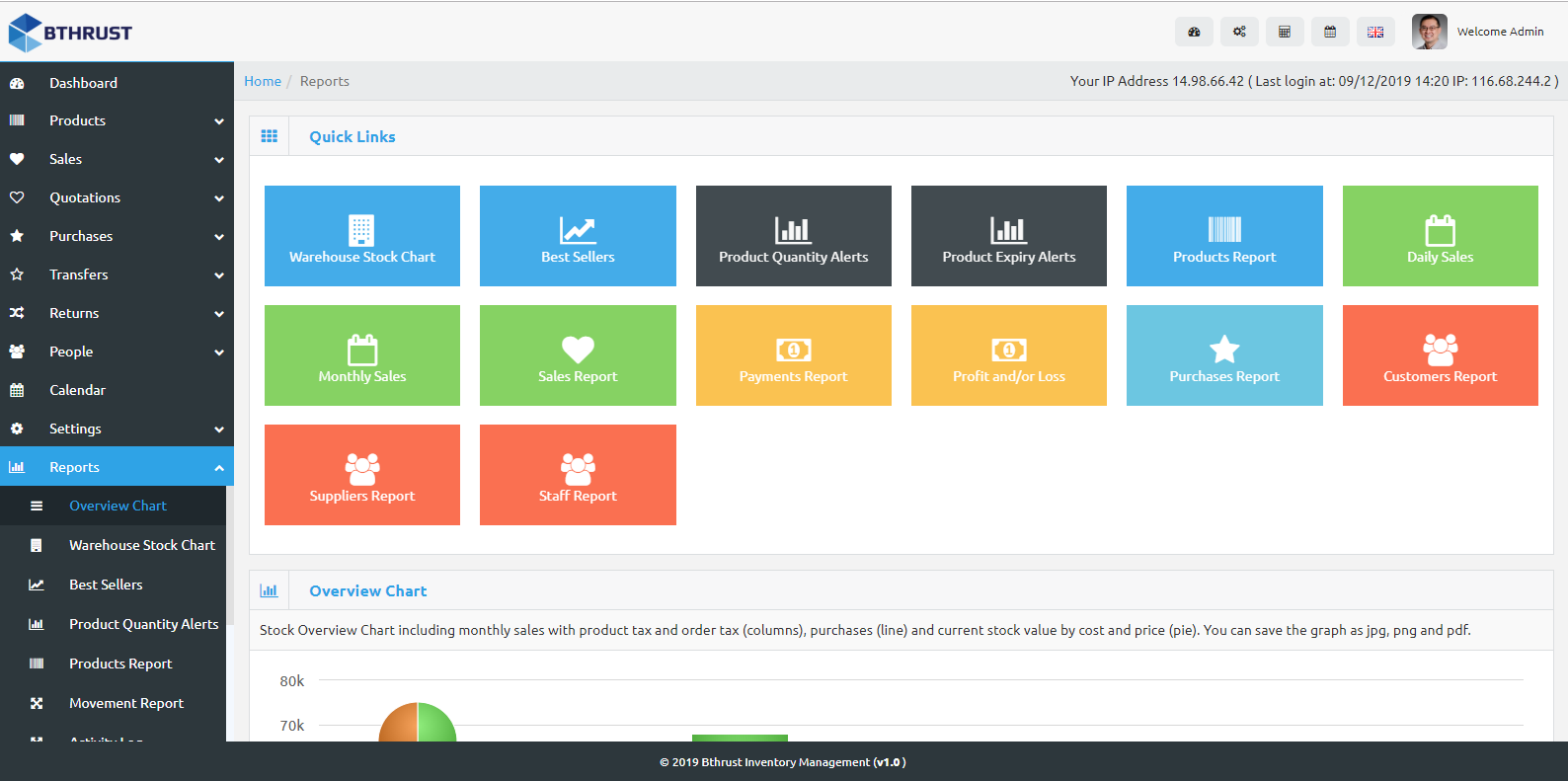

- Reporting and analytics:Generate reports and analytics to track inventory performance, identify trends, and make better decisions.

- Integration with other business systems:Integrate your inventory management system with your other business systems, such as your accounting software or e-commerce platform, to streamline your operations.

- Mobile access:Access your inventory management system from anywhere using a mobile device.

Benefits of Implementing an Inventory Management System: Inventory Management System Small Business

Implementing an inventory management system (IMS) can provide significant benefits for small businesses, streamlining operations, reducing costs, and improving efficiency. By automating inventory tracking, businesses can gain real-time visibility into their stock levels, optimize ordering, and minimize waste.

Cost Savings

- Reduced carrying costs:IMS helps businesses optimize inventory levels, reducing the risk of overstocking and associated storage and insurance expenses.

- Lower ordering costs:By optimizing inventory levels and automating reordering, businesses can reduce the frequency of orders, resulting in lower shipping and handling costs.

- Reduced shrinkage and loss:IMS helps businesses track inventory more accurately, minimizing the risk of theft, damage, or spoilage.

Efficiency Gains

- Improved order fulfillment:Real-time inventory visibility enables businesses to fulfill orders accurately and efficiently, reducing the risk of delays or backorders.

- Enhanced customer satisfaction:Accurate inventory information ensures that customers receive the products they ordered on time, improving customer satisfaction and loyalty.

- Time savings:IMS automates many inventory management tasks, such as tracking, reordering, and reporting, freeing up valuable time for business owners and employees.

Quantifying the Benefits

The specific cost savings and efficiency gains achieved through IMS implementation vary depending on the business and industry. However, studies have shown that small businesses can typically reduce inventory costs by 10-20% and increase inventory turnover by 20-50%.

Best Practices for Inventory Management

Effective inventory management is crucial for small businesses to optimize their operations, minimize costs, and enhance customer satisfaction. Here are some best practices to consider:

Optimizing Inventory Levels, Inventory management system small business

Maintaining optimal inventory levels helps businesses avoid overstocking or understocking. Overstocking leads to increased storage costs, product obsolescence, and potential losses. Understocking, on the other hand, can result in lost sales, customer dissatisfaction, and reputational damage. To optimize inventory levels, businesses should:

- Establish safety stock levels to buffer against unexpected demand fluctuations.

- Use forecasting techniques to predict future demand and adjust inventory levels accordingly.

- Implement a regular inventory audit process to identify and correct discrepancies.

Reducing Waste

Minimizing waste is essential for cost reduction and environmental sustainability. Businesses can reduce waste by:

- Implementing a first-in, first-out (FIFO) inventory management system to ensure older products are sold first.

- Identifying and eliminating slow-moving or obsolete items.

- Optimizing packaging and storage methods to prevent damage and spoilage.

Improving Accuracy

Accurate inventory records are crucial for effective decision-making. To improve accuracy, businesses should:

- Use barcode scanning or RFID technology for real-time inventory tracking.

- Conduct regular physical inventory counts and reconcile them with inventory records.

- Train staff on proper inventory management procedures and ensure compliance.

Case Studies and Examples

To illustrate the effectiveness of inventory management systems, let’s explore case studies of small businesses that have successfully implemented them.

These examples showcase the tangible results and valuable lessons learned, highlighting the transformative impact of inventory management solutions on business operations.

Case Study: XYZ Retail Store

XYZ Retail Store, a local clothing boutique, struggled with stockouts and overstocking, leading to lost sales and excess inventory costs. After implementing an inventory management system, they experienced:

- Reduced stockouts by 40%, improving customer satisfaction and sales revenue.

- Optimized inventory levels, decreasing excess inventory by 25%, freeing up cash flow.

- Enhanced inventory visibility, enabling real-time tracking and better decision-making.

Future Trends in Inventory Management

The rapid advancement of technology has significantly impacted various industries, and inventory management is no exception. Several emerging trends are shaping the future of inventory management, promising to revolutionize the way small businesses manage their stock.

Real-time Tracking

Real-time inventory tracking systems provide businesses with up-to-date visibility into their inventory levels. By leveraging technologies like RFID (Radio Frequency Identification) and IoT (Internet of Things), businesses can track the movement of their products throughout the supply chain. This real-time visibility enables businesses to make informed decisions, reduce stockouts, and optimize their inventory levels.

Artificial Intelligence and Machine Learning

AI and ML are transforming inventory management by automating tasks and providing predictive insights. AI-powered systems can analyze historical data, identify patterns, and forecast demand, enabling businesses to anticipate future needs and adjust their inventory levels accordingly. This proactive approach helps businesses avoid overstocking and understocking, resulting in reduced costs and improved customer satisfaction.

Cloud-based Inventory Management

Cloud-based inventory management systems offer several advantages to small businesses. They provide access to real-time data from anywhere with an internet connection, enabling businesses to manage their inventory remotely. Cloud-based systems also eliminate the need for expensive hardware and IT infrastructure, making them a cost-effective option for small businesses.

Blockchain Technology

Blockchain technology has the potential to revolutionize inventory management by providing a secure and transparent way to track the movement of goods. Blockchain-based systems can create an immutable record of transactions, ensuring the accuracy and integrity of inventory data. This enhanced transparency can improve collaboration among supply chain partners and reduce the risk of fraud and counterfeiting.

Voice-activated Inventory Management

Voice-activated inventory management systems allow businesses to manage their inventory using voice commands. This hands-free approach can improve efficiency, particularly in warehouses and distribution centers. Voice-activated systems can also reduce errors and increase productivity by allowing employees to focus on other tasks while managing their inventory.

Final Wrap-Up

By implementing an IMS, you can streamline your inventory management processes, reduce costs, and improve efficiency. This can free up your time and resources to focus on other aspects of your business, such as marketing and sales.

FAQ

What are the benefits of using an IMS?

IMSs can help you improve inventory accuracy, reduce costs, and streamline your inventory management processes.

What are the different types of IMSs?

There are two main types of IMSs: manual and software-based. Manual IMSs are typically used by small businesses with a limited number of products. Software-based IMSs are more comprehensive and can be used by businesses of all sizes.

How do I choose the right IMS for my business?

When choosing an IMS, you should consider the size of your business, the number of products you sell, and your budget.