Inventory management small business – Inventory management is crucial for small businesses, enabling them to streamline operations, optimize stock levels, and enhance profitability. Understanding its significance and implementing effective strategies can empower small businesses to overcome challenges and thrive in today’s competitive market.

Inventory Management for Small Businesses

Inventory management is the process of overseeing the flow of goods from purchase to sale. It involves tasks such as tracking inventory levels, forecasting demand, and optimizing stock levels to meet customer needs while minimizing waste and costs. Effective inventory management is crucial for small businesses as it can significantly impact their profitability, customer satisfaction, and overall operational efficiency.

Benefits of Effective Inventory Management

Effective inventory management offers numerous benefits for small businesses, including:

- Improved Cash Flow:By optimizing inventory levels, businesses can reduce the amount of capital tied up in unsold inventory, freeing up cash for other essential business operations.

- Reduced Storage Costs:Efficient inventory management can minimize the need for excessive storage space, resulting in lower storage costs.

- Increased Sales:Accurate inventory tracking ensures that businesses can meet customer demand, leading to increased sales and customer satisfaction.

- Reduced Waste:Effective inventory management helps businesses avoid overstocking and spoilage, reducing waste and associated costs.

- Improved Customer Service:By maintaining optimal inventory levels, businesses can promptly fulfill customer orders, enhancing customer satisfaction and loyalty.

Challenges Faced by Small Businesses in Managing Inventory

While inventory management is essential, small businesses often face challenges in this area:

- Limited Resources:Small businesses may have limited financial and human resources, making it difficult to implement robust inventory management systems.

- Fluctuating Demand:Small businesses may experience unpredictable demand patterns, making it challenging to forecast inventory needs accurately.

- Lack of Technology:Many small businesses rely on manual inventory tracking methods, which can be time-consuming and error-prone.

- Space Constraints:Small businesses often operate in limited spaces, making it challenging to store inventory efficiently.

- Competition:Small businesses may face intense competition from larger businesses with more sophisticated inventory management systems.

Types of Inventory Management Systems

Inventory management systems are software applications that help businesses track and manage their inventory. There are many different types of inventory management systems available, each with its own advantages and disadvantages.

The most common type of inventory management system is a perpetual inventory system. Perpetual inventory systems track inventory levels in real-time, so businesses can always see how much inventory they have on hand. This type of system is best for businesses that have a high volume of inventory or that need to track inventory levels closely.

Periodic Inventory Systems

Periodic inventory systems track inventory levels at regular intervals, such as monthly or quarterly. This type of system is best for businesses that have a low volume of inventory or that do not need to track inventory levels closely.

Hybrid Inventory Systems

Hybrid inventory systems combine features of both perpetual and periodic inventory systems. Hybrid inventory systems track inventory levels in real-time, but they also perform periodic inventory counts to verify inventory levels.

Choosing the Right Inventory Management System

The best inventory management system for a small business will depend on the business’s specific needs. Businesses should consider the following factors when choosing an inventory management system:

- The volume of inventory the business has

- The frequency with which the business needs to track inventory levels

- The level of accuracy the business needs

- The budget the business has

Inventory Tracking and Control

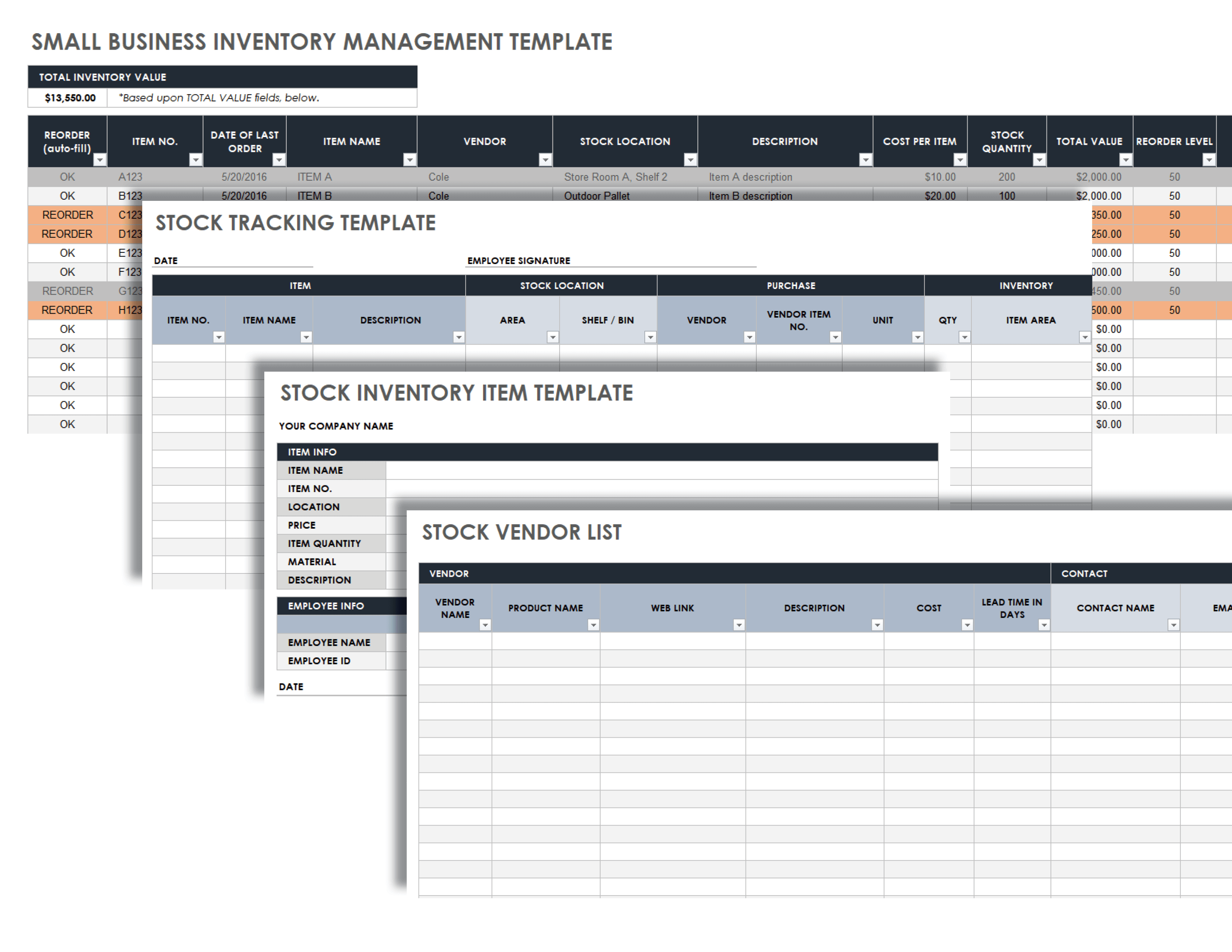

Accurate inventory tracking is crucial for small businesses to maintain optimal stock levels, minimize losses, and enhance profitability. It allows businesses to monitor the flow of goods, identify discrepancies, and make informed decisions regarding inventory management.Effective inventory tracking methods include manual systems (e.g., spreadsheets, checklists) and automated systems (e.g., inventory management software).

Businesses should select a method that aligns with their size, product range, and budget.

Implementing Effective Inventory Control Measures

To implement effective inventory control measures, businesses can:

- Establish clear inventory policies and procedures.

- Conduct regular inventory audits to verify physical counts against records.

- Implement a system for tracking inventory movement (e.g., FIFO, LIFO).

- Use technology to automate inventory tracking and minimize errors.

- Set safety stock levels to prevent stockouts.

By implementing these measures, small businesses can gain greater visibility into their inventory levels, reduce shrinkage, and improve overall inventory management efficiency.

Inventory Optimization Techniques

Inventory optimization is a crucial aspect of inventory management, enabling businesses to maintain optimal inventory levels while minimizing costs. By optimizing inventory, small businesses can improve cash flow, reduce waste, and enhance customer satisfaction.

There are several techniques for optimizing inventory levels:

Just-in-Time (JIT) Inventory

JIT aims to keep inventory levels as low as possible by ordering items only when they are needed. This approach reduces storage costs, waste, and the risk of obsolescence. JIT requires close coordination with suppliers and a reliable supply chain.

Economic Order Quantity (EOQ)

EOQ is a formula that determines the optimal quantity to order at a time to minimize total inventory costs. It considers factors such as demand, ordering costs, and holding costs.

Safety Stock, Inventory management small business

Safety stock is an additional amount of inventory held to buffer against unexpected fluctuations in demand or supply chain disruptions. It helps prevent stockouts and ensures uninterrupted operations.

Vendor-Managed Inventory (VMI)

VMI allows suppliers to manage inventory levels on behalf of their customers. The supplier monitors inventory levels and replenishes stock as needed, ensuring optimal levels and reducing the burden on the customer.

Consignment Inventory

Consignment inventory is similar to VMI, but the customer does not take ownership of the inventory until it is sold. The supplier retains ownership and is responsible for managing inventory levels.

Inventory Management Software: Inventory Management Small Business

Inventory management software is a valuable tool for small businesses, providing numerous benefits and streamlining operations. These software solutions offer real-time visibility into inventory levels, automating tasks, and providing valuable insights for better decision-making.

Features to Consider

When choosing inventory management software, consider the following features:

- Inventory Tracking:Tracks inventory levels, locations, and movement.

- Order Management:Automates order processing, tracking, and fulfillment.

- Demand Forecasting:Predicts future demand based on historical data.

- Replenishment Management:Automates inventory replenishment to maintain optimal levels.

- Reporting and Analytics:Provides detailed reports on inventory performance, trends, and insights.

Best Practices for Small Business Inventory Management

Effective inventory management is crucial for small businesses to optimize cash flow, minimize waste, and enhance customer satisfaction. Here are some best practices to guide you:

- Forecast demand accurately:Understanding customer demand patterns and trends helps businesses anticipate future needs and avoid overstocking or understocking.

- Manage stock levels efficiently:Determine optimal stock levels to meet demand without tying up excessive capital or facing stockouts. Use inventory tracking tools to monitor stock levels in real-time.

- Optimize inventory turnover:Calculate inventory turnover ratio to assess how efficiently inventory is being used. Aim to improve turnover by reducing lead times, optimizing order quantities, and minimizing obsolete stock.

- Implement inventory control measures:Establish clear inventory control procedures, including regular stock counts, cycle counting, and inventory audits. This helps prevent theft, shrinkage, and errors.

- Leverage technology:Utilize inventory management software or apps to automate tasks, improve accuracy, and gain real-time visibility into inventory levels.

- Collaborate with suppliers:Build strong relationships with suppliers to ensure timely delivery, negotiate favorable terms, and minimize disruptions.

- Monitor inventory performance:Regularly review inventory metrics, such as inventory turnover, stockout rates, and carrying costs. This helps identify areas for improvement and optimize inventory management strategies.

Final Review

By embracing inventory management best practices, utilizing technology, and continuously optimizing processes, small businesses can gain a competitive edge, minimize waste, and maximize their revenue potential.

FAQ Overview

What are the benefits of inventory management for small businesses?

Effective inventory management helps reduce waste, optimize stock levels, improve cash flow, enhance customer satisfaction, and streamline operations.

What challenges do small businesses face in managing inventory?

Small businesses often struggle with limited resources, forecasting demand accurately, managing stock levels, and preventing stockouts.

What are the key inventory management techniques for small businesses?

Small businesses can employ techniques such as inventory tracking, inventory optimization, safety stock management, and forecasting to effectively manage their inventory.