Business inventory tracking plays a crucial role in the success of any business, providing valuable insights into stock levels, costs, and customer demand. By effectively tracking inventory, businesses can optimize their operations, improve customer satisfaction, and stay ahead in the competitive market.

Inventory tracking involves monitoring the flow of goods, from the moment they are received until they are sold or used in production. This process helps businesses maintain accurate records of their inventory, allowing them to make informed decisions about purchasing, production, and sales.

Inventory Tracking Overview

Inventory tracking is a crucial aspect of business operations, enabling businesses to monitor and manage their stock levels effectively. It involves keeping a detailed record of all items held in stock, including their quantities, locations, and values. This information is essential for ensuring smooth business operations, minimizing losses, and optimizing profitability.

Types of Inventory Tracking Methods

There are various inventory tracking methods, each with its own advantages and disadvantages. Common methods include:

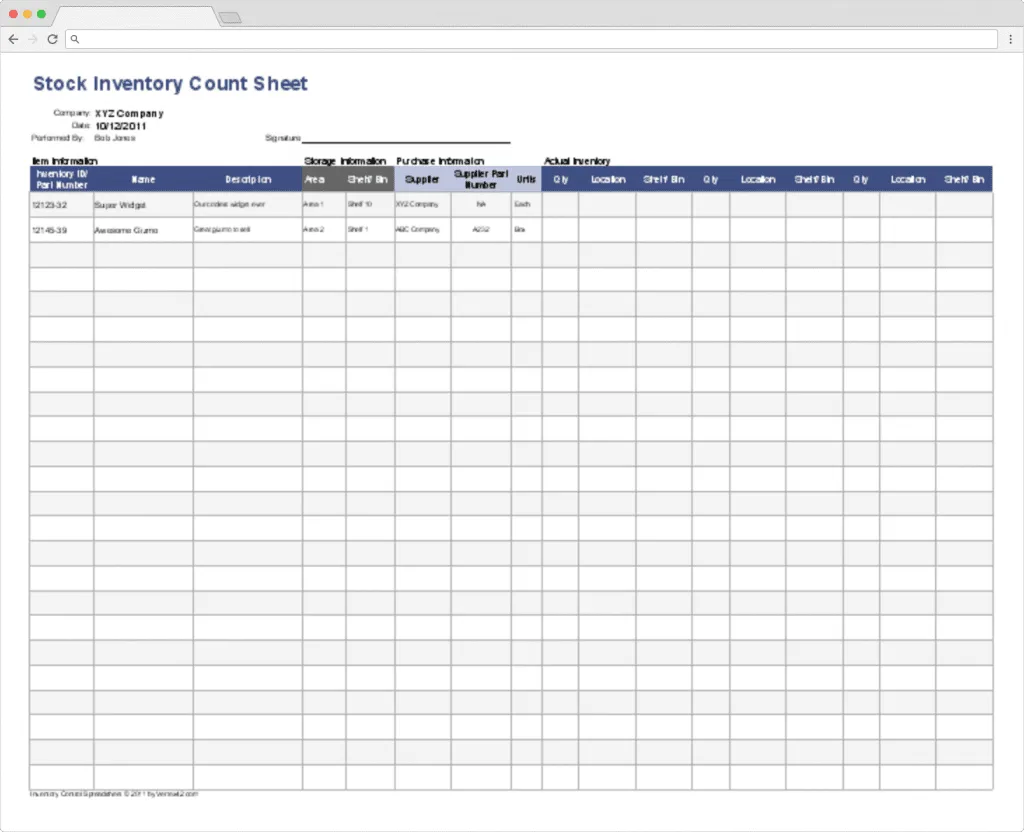

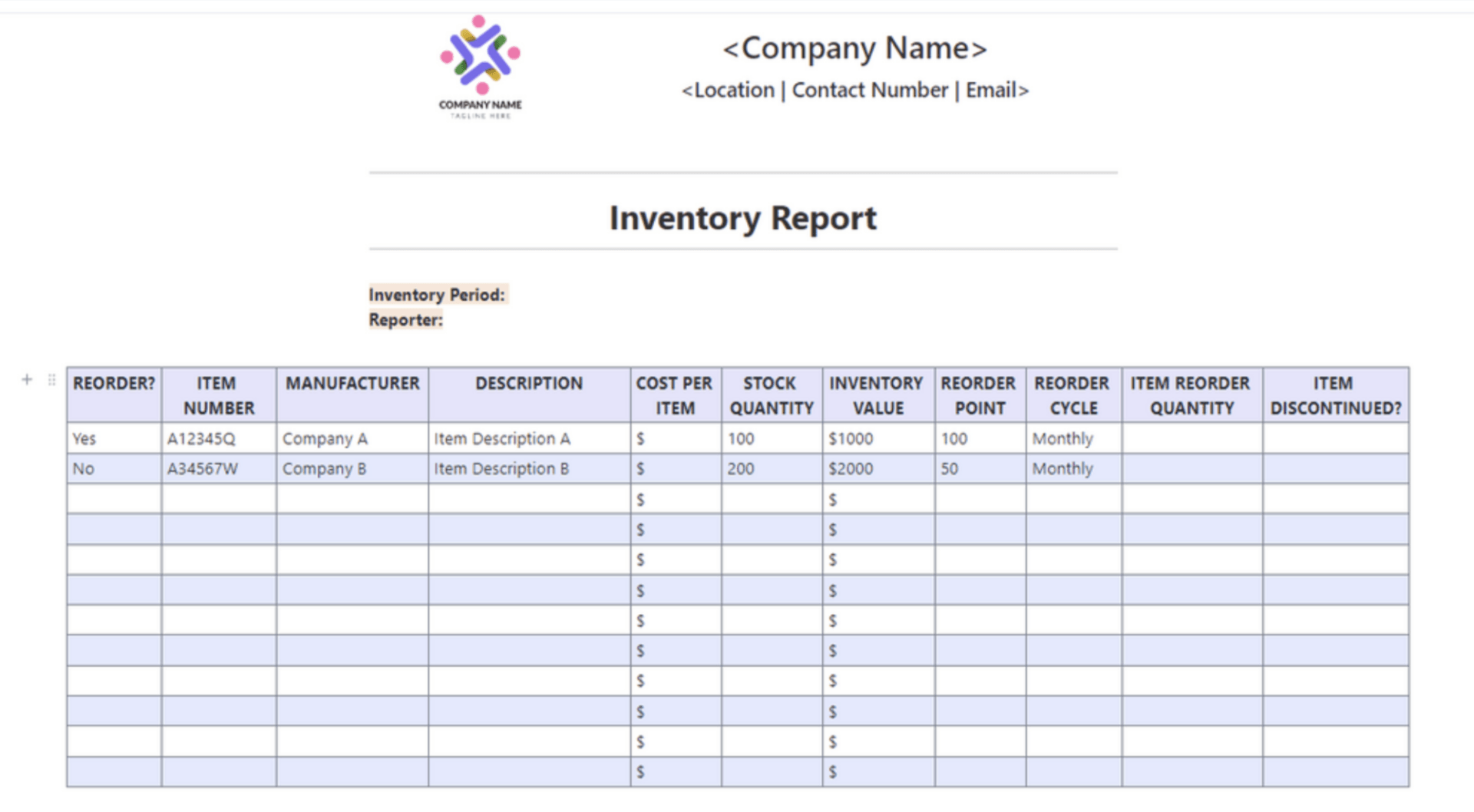

- Manual Inventory Tracking:Involves physically counting and recording inventory levels manually using pen and paper or spreadsheets. This method is relatively simple and cost-effective but can be time-consuming and prone to errors.

- Automated Inventory Tracking:Utilizes software or electronic devices, such as barcode scanners or RFID tags, to capture and track inventory data. This method offers greater accuracy and efficiency but requires investment in technology and training.

- Just-in-Time (JIT) Inventory Tracking:Aims to minimize inventory levels by ordering items only when needed. This method reduces storage costs and the risk of obsolescence but requires close coordination with suppliers.

- Periodic Inventory Tracking:Involves counting inventory at regular intervals, such as monthly or quarterly. This method provides a snapshot of inventory levels but can be labor-intensive and disruptive to operations.

Inventory Tracking Systems

Numerous inventory tracking systems are available, ranging from simple spreadsheets to sophisticated software solutions. Some popular options include:

- Microsoft Excel:A widely used spreadsheet software that allows businesses to create custom inventory tracking templates and manually enter data.

- QuickBooks:An accounting software that offers inventory tracking capabilities, including features for tracking multiple warehouses and managing stock levels.

- SAP Business One:A comprehensive enterprise resource planning (ERP) system that includes inventory tracking as a core module.

- Fishbowl Inventory:A dedicated inventory management software designed specifically for small and medium-sized businesses.

The choice of inventory tracking system depends on the size and complexity of the business, as well as its specific needs and budget.

Benefits of Inventory Tracking

![]()

Effective inventory tracking brings a plethora of advantages that can significantly enhance your business operations and customer satisfaction. From cost savings to improved customer service, inventory tracking is a crucial tool for optimizing your supply chain and ensuring a smooth flow of goods.

Cost-Saving Advantages, Business inventory tracking

- Reduced storage costs:Accurate inventory tracking helps you identify and eliminate excess stock, reducing the need for costly storage space.

- Lower carrying costs:By tracking inventory levels, you can optimize your inventory levels, minimizing carrying costs associated with holding excessive stock.

- Reduced waste and spoilage:Effective inventory management helps prevent overstocking, reducing the risk of spoilage, obsolescence, and waste.

Improved Customer Satisfaction

- Increased availability:Accurate inventory tracking ensures you have the right products in stock when customers need them, leading to higher customer satisfaction and loyalty.

- Faster order fulfillment:Real-time inventory visibility enables faster order processing and fulfillment, reducing customer wait times and improving overall satisfaction.

- Reduced backorders:By monitoring inventory levels, you can proactively identify potential stockouts and place replenishment orders in a timely manner, minimizing backorders and customer disappointment.

Preventing Stockouts and Overstocking

- Avoidance of stockouts:Inventory tracking helps you predict demand and adjust inventory levels accordingly, minimizing the risk of stockouts that can lead to lost sales and dissatisfied customers.

- Prevention of overstocking:Accurate inventory tracking helps you identify and reduce excess stock, preventing the accumulation of slow-moving or obsolete items that tie up valuable capital.

- Optimized inventory levels:By tracking inventory levels, you can find the optimal balance between having enough stock to meet demand without overstocking, reducing costs and improving efficiency.

Challenges of Inventory Tracking

Inventory tracking presents several challenges that businesses must navigate to maintain accurate records and efficient operations.

One significant challenge lies in human error. Manual processes and data entry are prone to mistakes, such as miscounting items, entering incorrect quantities, or failing to update records promptly. These errors can lead to discrepancies between physical inventory and the recorded data, resulting in inaccuracies and inefficiencies.

Difficulties of Tracking Inventory in Multiple Locations

For businesses with multiple warehouses or distribution centers, tracking inventory across various locations can be complex. Maintaining synchronized and up-to-date inventory data across different sites requires effective communication and coordination. Delays in updating inventory levels, discrepancies in stock counts, and challenges in managing transfers between locations can hinder efficient inventory management.

Best Practices for Inventory Tracking: Business Inventory Tracking

Implementing an effective inventory tracking system is crucial for businesses to optimize their operations and avoid stockouts. Here’s a step-by-step guide:

- Establish clear inventory goals:Define the specific objectives you aim to achieve with inventory tracking, such as reducing waste, improving customer satisfaction, or optimizing cash flow.

- Choose the right inventory tracking method:Select a method that aligns with your business size, product types, and budget. Options include manual systems, spreadsheets, or inventory management software.

- Implement a consistent inventory counting process:Establish a regular schedule for counting inventory and follow it meticulously. Use scanning technology or mobile devices for accuracy and efficiency.

- Train staff on inventory management procedures:Ensure that all employees involved in inventory management are trained on proper counting, storage, and record-keeping practices.

- Regularly review and adjust inventory levels:Monitor inventory levels closely and make adjustments based on sales trends, seasonal fluctuations, and supplier lead times.

Maintaining Accurate Inventory Records

Maintaining accurate inventory records is essential for effective tracking. Here are some tips:

- Use a centralized inventory database:Store all inventory data in a single, easily accessible location to prevent discrepancies and ensure consistency.

- Conduct regular inventory audits:Periodically verify the accuracy of inventory records by comparing them to physical counts.

- Implement cycle counting:Break down the inventory audit process into smaller, more manageable cycles to identify discrepancies early on.

- Use technology to automate inventory updates:Utilize barcode scanners, RFID tags, or inventory management software to automate inventory updates and reduce errors.

Inventory Tracking Tools

Inventory tracking tools are essential for businesses to manage their inventory effectively. These tools can help businesses track inventory levels, manage stock, and optimize inventory management processes.

There are a variety of inventory tracking software available, each with its own features and benefits. Some of the most popular inventory tracking software include:

- Fishbowl

- NetSuite

- QuickBooks

- SAP Business One

- Zoho Inventory

When choosing an inventory tracking software, it is important to consider the size of your business, the complexity of your inventory management needs, and your budget.

Advantages of Cloud-Based Inventory Tracking Systems

- Cloud-based inventory tracking systems are accessible from anywhere with an internet connection.

- They are typically more affordable than on-premise inventory tracking systems.

- They are easier to implement and maintain than on-premise systems.

- They offer a wider range of features than on-premise systems.

Disadvantages of Cloud-Based Inventory Tracking Systems

- Cloud-based inventory tracking systems can be less secure than on-premise systems.

- They can be slower than on-premise systems, especially if your internet connection is slow.

- They can be more difficult to customize than on-premise systems.

Mobile Inventory Tracking Apps

Mobile inventory tracking apps can streamline inventory management by allowing you to track inventory levels and manage stock on the go.

Mobile inventory tracking apps can be used to:

- Scan barcodes to track inventory levels

- Create and manage purchase orders

- Track shipments

- Manage stock levels

Mobile inventory tracking apps can save you time and money by automating inventory management tasks and providing you with real-time visibility into your inventory levels.

Inventory Tracking Metrics

Inventory tracking metrics provide valuable insights into the efficiency and effectiveness of your inventory management. By monitoring these metrics, businesses can make informed decisions to optimize their inventory levels, reduce costs, and improve customer satisfaction.

Key inventory tracking metrics include:

- Inventory turnover

- Inventory days on hand

- Inventory accuracy

- Fill rate

- Stockout rate

Inventory Turnover

Inventory turnover measures how quickly inventory is sold and replaced. It is calculated by dividing the cost of goods sold (COGS) by the average inventory value over a period.

Inventory Turnover = COGS / Average Inventory Value

A higher inventory turnover ratio indicates that inventory is being sold quickly, which is generally desirable. However, an excessively high turnover rate can lead to stockouts and lost sales, while a low turnover rate may indicate excess inventory and inefficient operations.

Inventory Days on Hand

Inventory days on hand measures the average number of days that inventory is held before being sold. It is calculated by dividing the average inventory value by the daily cost of goods sold.

Inventory Days on Hand = Average Inventory Value / Daily COGS

A shorter inventory days on hand indicates that inventory is being turned over more quickly, which is generally desirable. However, an excessively short inventory days on hand may lead to stockouts, while a long inventory days on hand may indicate excess inventory and inefficient operations.

Importance of Inventory Tracking Metrics

Inventory tracking metrics provide valuable insights into the efficiency and effectiveness of inventory management. By monitoring these metrics, businesses can:

- Identify areas for improvement in inventory management practices

- Make informed decisions about inventory levels and purchasing

- Reduce costs associated with excess inventory or stockouts

- Improve customer satisfaction by ensuring product availability

Future Trends in Inventory Tracking

The future of inventory tracking is bright, with emerging technologies set to transform the way businesses manage their stock. Artificial intelligence (AI) and machine learning (ML) are already playing a significant role in inventory management, and their impact is only expected to grow in the years to come.

One of the most important trends in inventory tracking is the increasing adoption of real-time tracking systems. These systems provide businesses with up-to-the-minute visibility into their inventory levels, which can help them to avoid stockouts and improve their overall efficiency.

Role of Artificial Intelligence and Machine Learning

AI and ML are being used to automate many tasks in inventory management, such as demand forecasting and inventory optimization. This can help businesses to improve their accuracy and efficiency, and free up their employees to focus on other tasks.

- AI can be used to analyze historical data to identify patterns and trends in demand. This information can then be used to create more accurate forecasts, which can help businesses to avoid stockouts and overstocking.

- ML can be used to optimize inventory levels based on a variety of factors, such as demand, lead time, and safety stock. This can help businesses to reduce their inventory costs and improve their overall efficiency.

Importance of Real-Time Inventory Tracking

Real-time inventory tracking systems provide businesses with up-to-the-minute visibility into their inventory levels. This information can be used to improve accuracy and efficiency in a number of ways:

- Avoid stockouts:Real-time inventory tracking systems can help businesses to avoid stockouts by providing them with early warning of low inventory levels.

- Improve efficiency:Real-time inventory tracking systems can help businesses to improve their efficiency by providing them with the information they need to make better decisions about inventory management.

- Reduce costs:Real-time inventory tracking systems can help businesses to reduce their costs by helping them to avoid overstocking and stockouts.

Summary

In conclusion, business inventory tracking is an essential aspect of modern business operations. By embracing best practices, utilizing effective tools, and leveraging emerging technologies, businesses can gain a competitive edge, optimize their supply chain, and ultimately drive profitability.

Expert Answers

What are the benefits of inventory tracking?

Inventory tracking provides numerous benefits, including cost savings, improved customer satisfaction, and reduced risk of stockouts or overstocking.

How can I implement an effective inventory tracking system?

Implementing an effective inventory tracking system involves following a step-by-step guide, maintaining accurate records, and conducting regular audits and cycle counting.

What are some common challenges in inventory tracking?

Common challenges in inventory tracking include human error, difficulties in tracking inventory in multiple locations, and the need for real-time data.