Delving into the realm of business inventory systems, we embark on a journey to unravel the intricacies of inventory management. From its fundamental concepts to the transformative benefits it offers, this system serves as the backbone of efficient operations and customer satisfaction.

Businesses across industries have harnessed the power of inventory systems, unlocking a wealth of advantages. Join us as we explore the essential features, types, and best practices of business inventory systems, empowering you to optimize your inventory management strategies and drive business success.

Inventory Management Fundamentals

Inventory management encompasses the processes involved in managing the flow of goods within a business. It plays a crucial role in ensuring that businesses have the right products, in the right quantities, at the right time, and at the right cost.

Effective inventory management helps businesses optimize their operations, reduce costs, and improve customer satisfaction.

Importance of Inventory Optimization

Optimizing inventory levels is essential for businesses as it allows them to:

- Reduce holding costs: Excessive inventory can lead to increased storage costs, insurance expenses, and the risk of obsolescence.

- Improve cash flow: Maintaining optimal inventory levels frees up cash that can be invested in other areas of the business.

- Enhance customer satisfaction: Having the right products in stock at the right time helps meet customer demand and reduce the risk of stockouts.

- Minimize waste: Effective inventory management helps reduce the likelihood of overstocking and spoilage, minimizing product waste.

Types of Inventory Systems

There are several types of inventory systems that businesses can implement, each with its own advantages and disadvantages:

- Periodic inventory system: Inventory is counted and recorded periodically, typically at the end of each accounting period.

- Perpetual inventory system: Inventory is continuously tracked and updated as transactions occur, providing real-time visibility into inventory levels.

- Just-in-time (JIT) inventory system: Inventory is ordered and received only when needed, minimizing inventory holding costs.

- Consignment inventory system: The supplier retains ownership of the inventory until it is sold, reducing the risk of loss for the business.

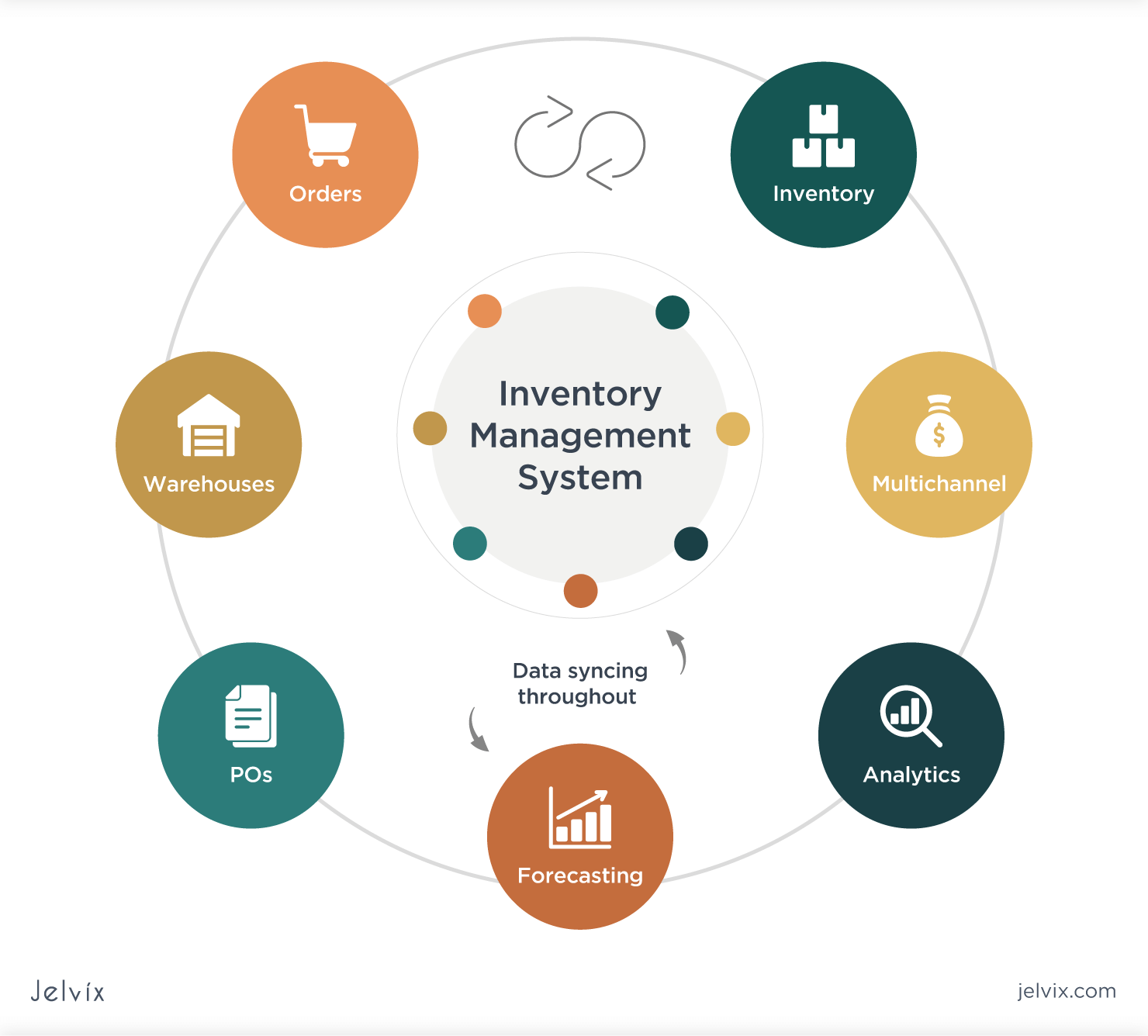

Key Features of a Business Inventory System

An effective business inventory system is the backbone of efficient inventory management. It provides businesses with the necessary tools to track, manage, and optimize their inventory levels, ensuring optimal stock levels and streamlined operations.

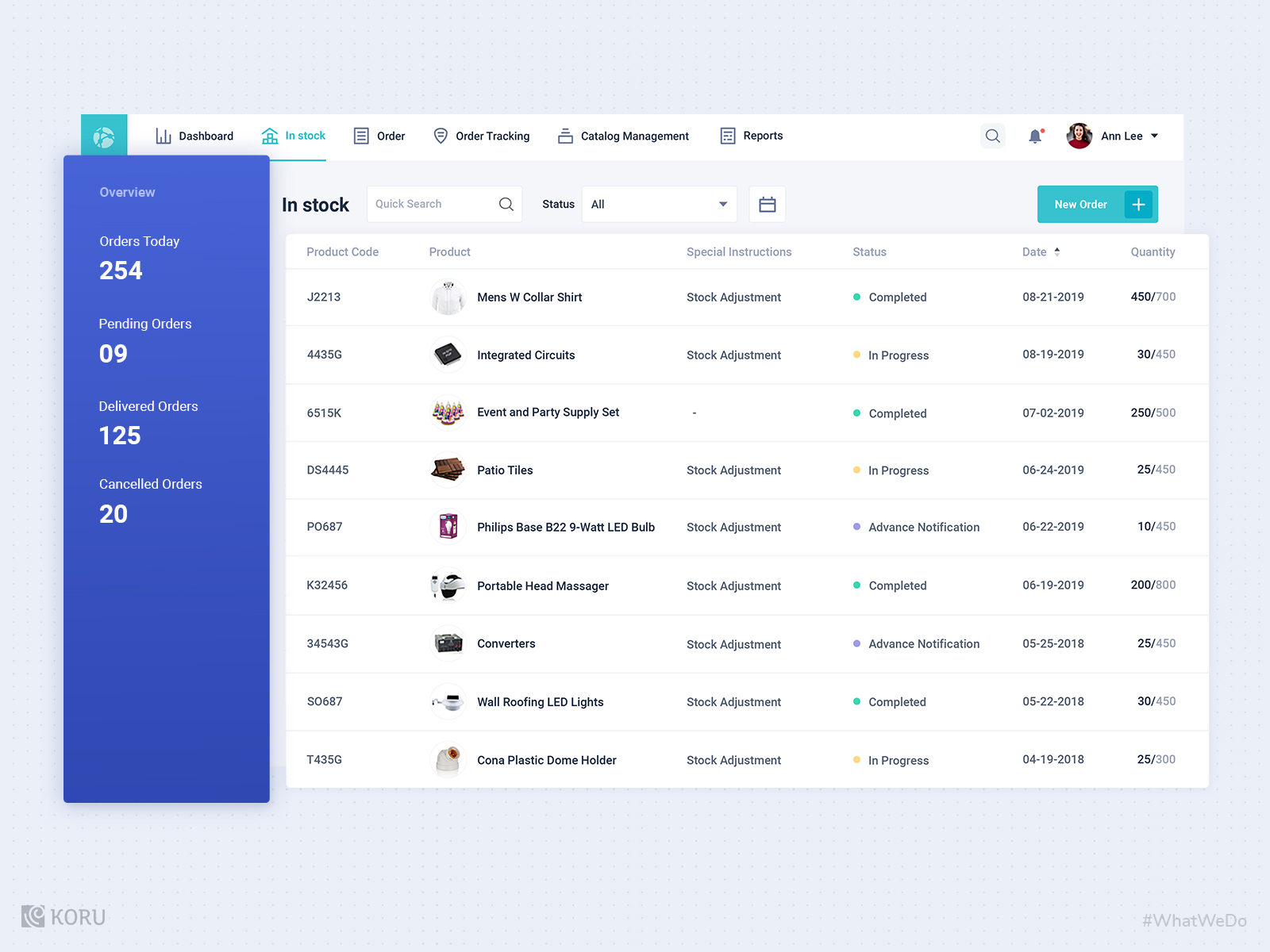

Key features of a robust business inventory system include real-time tracking, automated reordering, and comprehensive reporting capabilities. These features work together to provide businesses with a clear and up-to-date view of their inventory, enabling them to make informed decisions and improve their inventory management processes.

Real-Time Tracking

Real-time tracking provides businesses with a live view of their inventory levels, allowing them to monitor stock levels across multiple locations and channels in real time. This visibility enables businesses to identify potential stockouts or overstocks, preventing costly disruptions to operations and ensuring that customer orders can be fulfilled promptly.

Automated Reordering

Automated reordering automates the process of replenishing inventory, eliminating the need for manual intervention and reducing the risk of stockouts. By setting predefined reorder points and lead times, the system automatically generates purchase orders when inventory levels reach a certain threshold, ensuring that stock levels are maintained at optimal levels without overstocking.

Reporting Capabilities

Comprehensive reporting capabilities provide businesses with valuable insights into their inventory performance. These reports can include data on inventory turnover, stock levels, and sales trends, enabling businesses to identify areas for improvement and make data-driven decisions. By analyzing inventory reports, businesses can optimize their inventory levels, reduce carrying costs, and improve their overall inventory management efficiency.

Implementing a Business Inventory System

Implementing a business inventory system involves several crucial steps to ensure a smooth and successful integration. Planning, selecting the right system, and training staff are key components that contribute to the overall effectiveness of the system.

Planning

Thorough planning is essential before implementing an inventory system. Businesses should clearly define their inventory management goals, identify areas for improvement, and determine the specific requirements for their system. This includes considering factors such as the size and complexity of the business, the types of inventory managed, and the level of accuracy and control required.

Selecting the Right System

Choosing the right inventory system is critical to meeting the specific needs of a business. Various software solutions are available, each with its unique features and capabilities. Businesses should evaluate different systems based on factors such as functionality, ease of use, scalability, and integration with existing systems.

Training Staff

Proper training is crucial for staff to understand and effectively utilize the new inventory system. Businesses should provide comprehensive training to ensure that staff is well-versed in the system’s functionality, reporting capabilities, and inventory management best practices. This training should cover aspects such as data entry, inventory tracking, and system maintenance.

Ensuring a Smooth Implementation

To ensure a smooth implementation, businesses should:

- Establish clear communication channels between stakeholders

- Set realistic timelines and milestones

- Provide ongoing support and training to staff

- Monitor the system’s performance and make adjustments as needed

- Regularly review and optimize the system to enhance its effectiveness

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to optimize stock levels, minimize waste, and improve profitability. Here are some best practices to enhance inventory management processes:

To ensure accuracy and efficiency in inventory management, it’s essential to establish clear inventory policies and procedures. This includes defining roles and responsibilities, setting inventory targets, and outlining processes for receiving, storing, and issuing inventory.

Minimizing Waste

- Implement a first-in, first-out (FIFO) inventory system to ensure older stock is used first, reducing the risk of spoilage or obsolescence.

- Conduct regular inventory audits to identify and remove obsolete or damaged items, preventing unnecessary storage costs and potential losses.

- Utilize inventory forecasting techniques to predict demand and optimize stock levels, minimizing the likelihood of overstocking or stockouts.

Optimizing Stock Levels

- Establish safety stock levels to buffer against unexpected demand fluctuations, preventing stockouts and ensuring customer satisfaction.

- Implement a just-in-time (JIT) inventory system to reduce holding costs and improve inventory turnover, ensuring a lean and efficient supply chain.

- Utilize inventory optimization software to analyze inventory data, identify trends, and make informed decisions about stock levels and replenishment strategies.

Improving Inventory Turnover, Business inventory system

- Regularly review inventory turnover rates to identify slow-moving items and implement strategies to increase their sales, such as promotions or discounts.

- Implement vendor-managed inventory (VMI) systems to allow suppliers to manage inventory levels, ensuring timely replenishment and reducing stockouts.

- Utilize cross-docking techniques to eliminate unnecessary storage and handling, improving inventory turnover and reducing lead times.

Examples of Successful Implementation

Amazon, a global e-commerce giant, leverages advanced inventory management practices to optimize its vast inventory. The company uses machine learning algorithms to forecast demand, implement JIT inventory systems, and reduce waste through efficient inventory tracking and management.

Toyota, renowned for its lean manufacturing practices, employs the Kanban system to manage inventory levels. Kanban cards are used to signal when inventory needs to be replenished, ensuring a continuous flow of materials and minimizing waste.

Future Trends in Inventory Management

Inventory management is on the cusp of a revolution, driven by technological advancements and the increasing availability of data. These trends are reshaping the way businesses manage their inventory, enabling them to become more efficient, responsive, and profitable.

One of the most significant trends in inventory management is the rise of automation. Automated systems can handle many of the tasks that were once performed manually, such as tracking inventory levels, placing orders, and managing shipments. This can free up employees to focus on more strategic tasks, such as developing new products and improving customer service.

Role of Technology

Technology is playing a major role in the evolution of inventory management. Cloud-based inventory management systems are becoming increasingly popular, as they offer a number of advantages over traditional on-premise systems. Cloud-based systems are more scalable, flexible, and cost-effective, and they can be accessed from anywhere with an internet connection.

Another important trend in inventory management is the use of data analytics. Data analytics can be used to track inventory trends, identify patterns, and predict future demand. This information can help businesses make better decisions about their inventory levels, and it can also help them avoid stockouts and overstocking.

How Businesses Can Prepare

Businesses can prepare for the future of inventory management by investing in technology and data analytics. They should also develop a comprehensive inventory management strategy that takes into account the latest trends. By following these steps, businesses can position themselves to succeed in the rapidly changing world of inventory management.

Ultimate Conclusion: Business Inventory System

In the ever-evolving landscape of inventory management, businesses must embrace emerging trends and leverage technology to stay ahead. By adopting innovative solutions and data-driven insights, organizations can anticipate future challenges and position themselves for continued growth. As we conclude our exploration of business inventory systems, remember that effective inventory management is not just about tracking stock levels; it’s about gaining a competitive edge, enhancing customer experiences, and driving profitability.

Q&A

What are the core principles of inventory management?

Inventory management encompasses the planning, organizing, and controlling of inventory to meet customer demand while minimizing costs and maximizing efficiency.

How can a business inventory system improve efficiency?

By automating tasks, providing real-time visibility, and optimizing stock levels, a business inventory system streamlines inventory processes, reducing time and effort.

What are the essential features of a robust business inventory system?

Real-time tracking, automated reordering, reporting capabilities, and integration with other business systems are crucial features for effective inventory management.

What are the different types of business inventory systems?

Common types include perpetual inventory systems, periodic inventory systems, and just-in-time inventory systems, each with its own advantages and disadvantages.

How can businesses ensure a successful implementation of a business inventory system?

Planning, selecting the right system, training staff, and continuous monitoring are key factors for a smooth and successful implementation.