Business inventory programs empower businesses to effectively manage their inventory, reducing costs, enhancing efficiency, and elevating customer satisfaction. These programs streamline operations, providing real-time visibility into inventory levels, optimizing stock levels, and automating inventory tracking.

From small businesses to large enterprises, inventory programs offer a range of solutions tailored to specific industry needs. By leveraging technology and data analytics, businesses can gain valuable insights into their inventory performance, enabling them to make informed decisions that drive growth and profitability.

Inventory Management Benefits

Implementing business inventory programs offers numerous advantages that can significantly enhance operational efficiency and profitability.

Inventory programs streamline operations, leading to cost reduction, improved efficiency, and enhanced customer satisfaction. These programs provide real-time visibility into inventory levels, enabling businesses to optimize stock levels, reduce waste, and avoid stockouts.

Cost Reduction

- Reduced carrying costs: Inventory programs help businesses optimize stock levels, reducing the need for excess inventory and associated storage and maintenance costs.

- Lower procurement costs: Accurate inventory data allows businesses to negotiate better deals with suppliers by consolidating orders and leveraging economies of scale.

- Reduced waste: Inventory programs help identify and prevent overstocking, minimizing the risk of obsolete or damaged inventory.

Improved Efficiency

- Streamlined order fulfillment: Real-time inventory visibility enables businesses to process orders faster and more accurately, reducing shipping delays and improving customer satisfaction.

- Enhanced warehouse management: Inventory programs provide a centralized view of inventory across multiple locations, optimizing storage and retrieval processes.

- Reduced manual labor: Automated inventory tracking and replenishment systems eliminate the need for manual counting and data entry, saving time and reducing errors.

Enhanced Customer Satisfaction

- Reduced stockouts: Inventory programs help businesses maintain optimal stock levels, minimizing the likelihood of stockouts and ensuring customer orders can be fulfilled promptly.

- Improved delivery times: Streamlined order fulfillment processes enabled by inventory programs reduce shipping delays and improve customer satisfaction.

- Increased customer loyalty: Consistent product availability and prompt delivery foster customer trust and loyalty.

Types of Inventory Programs

Inventory programs provide businesses with a comprehensive range of tools and features to manage their inventory efficiently. Different types of inventory programs cater to the specific needs and complexities of businesses, offering varying levels of functionality and customization.

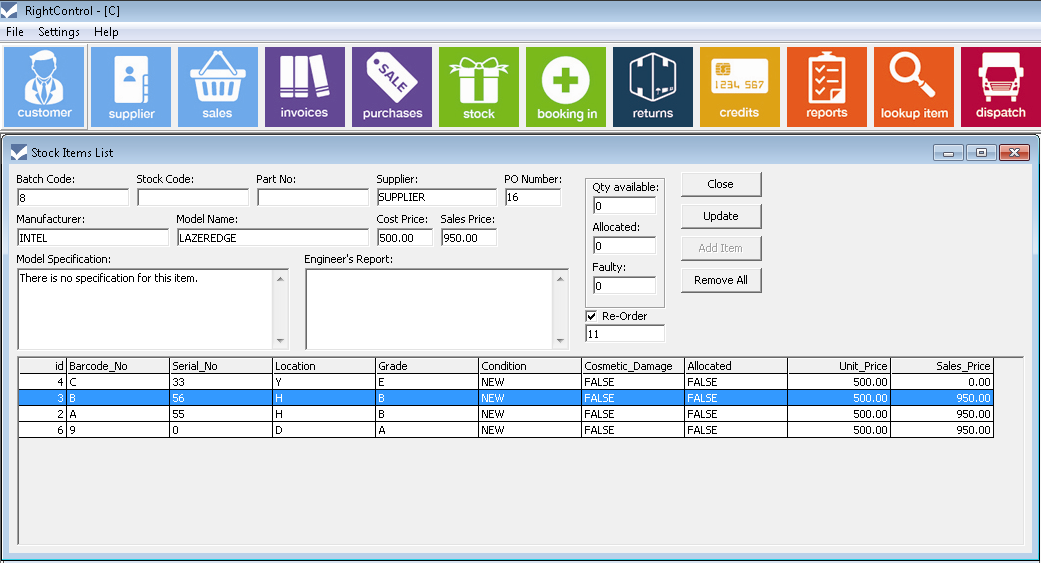

On-Premise Inventory Programs

- Installed on the business’s own servers

- Provide complete control over data and customization

- Higher upfront costs for hardware and maintenance

- Suitable for businesses with complex inventory needs and high security requirements

Cloud-Based Inventory Programs

- Hosted on a third-party server

- Accessible from anywhere with an internet connection

- Lower upfront costs and reduced maintenance responsibilities

- Suitable for businesses of all sizes and with varying inventory complexity

Hybrid Inventory Programs

- Combine elements of both on-premise and cloud-based programs

- Provide flexibility and customization options

- Suitable for businesses with unique or evolving inventory management needs

Comparison of Inventory Programs

| Feature | On-Premise | Cloud-Based | Hybrid |

|---|---|---|---|

| Data Control | Complete control | Shared control | Flexible control |

| Customization | High | Moderate | Variable |

| Cost | High upfront | Lower upfront | Variable |

| Accessibility | Limited to local network | Accessible from anywhere | Variable |

| Security | High | Shared responsibility | Variable |

Inventory Tracking Methods

Inventory tracking is a critical aspect of inventory management, ensuring accuracy, visibility, and efficient control over stock levels. Various methods are employed to track inventory, each with its advantages and disadvantages.

The choice of inventory tracking method depends on factors such as the size and complexity of the business, the nature of the products, and the desired level of accuracy and control.

Physical Inventory Tracking

Physical inventory tracking involves manually counting and recording the physical inventory at regular intervals. This method is straightforward and provides a direct count of the inventory on hand.

- Pros:Accurate, easy to implement, and relatively inexpensive.

- Cons:Time-consuming, prone to human error, and requires inventory to be halted during the counting process.

Periodic Inventory Tracking

Periodic inventory tracking involves calculating inventory levels at specific intervals, typically monthly or quarterly. It is less labor-intensive than physical inventory tracking and can be automated using inventory management software.

- Pros:Less time-consuming than physical inventory tracking, provides periodic snapshots of inventory levels.

- Cons:Less accurate than physical inventory tracking, may not reflect real-time inventory levels.

Perpetual Inventory Tracking

Perpetual inventory tracking continuously updates inventory levels based on transactions. It provides real-time visibility into inventory levels and can be integrated with point-of-sale (POS) systems and other business applications.

- Pros:Accurate, provides real-time inventory levels, reduces the risk of stockouts.

- Cons:More complex and expensive to implement than other methods, requires accurate data entry.

Cycle Counting

Cycle counting involves counting a portion of the inventory regularly, typically on a rotating basis. It helps to identify and correct errors in inventory records and provides an ongoing check on inventory accuracy.

- Pros:Helps to maintain inventory accuracy, reduces the risk of large inventory discrepancies.

- Cons:Can be time-consuming, requires training and discipline to execute effectively.

| Method | Pros | Cons | Applications |

|---|---|---|---|

| Physical Inventory Tracking | Accurate, easy to implement, inexpensive | Time-consuming, prone to human error | Small businesses, low-volume inventory |

| Periodic Inventory Tracking | Less time-consuming, provides periodic snapshots | Less accurate, may not reflect real-time levels | Medium-sized businesses, moderate inventory turnover |

| Perpetual Inventory Tracking | Accurate, real-time visibility, reduces stockouts | Complex, expensive to implement, requires accurate data entry | Large businesses, high-volume inventory |

| Cycle Counting | Maintains accuracy, reduces large discrepancies | Time-consuming, requires training and discipline | Businesses with high-value or critical inventory |

Inventory Optimization Techniques: Business Inventory Programs

Optimizing inventory levels is crucial for businesses to meet demand, minimize costs, and improve efficiency. Here are some techniques to optimize inventory levels:

Safety Stock

Safety stock refers to the extra inventory kept on hand to buffer against unexpected demand or supply disruptions. It ensures that businesses can meet customer orders even during peak demand or when there are delays in поставки.

Reorder Points

Reorder points indicate the inventory level at which a new order should be placed. Setting appropriate reorder points helps businesses avoid stockouts while minimizing the risk of overstocking.

Inventory Forecasting

Inventory forecasting involves predicting future demand to optimize inventory levels. By using historical data, market trends, and statistical models, businesses can forecast demand and adjust inventory levels accordingly.

Step-by-Step Guide to Implementing Optimization Strategies, Business inventory programs

- Establish clear inventory goals and objectives.

- Collect and analyze historical inventory data and demand patterns.

- Determine safety stock levels based on lead times, demand variability, and service levels.

- Set reorder points that trigger new orders when inventory reaches a predetermined level.

- Implement inventory forecasting techniques to predict future demand and adjust inventory levels accordingly.

- Monitor inventory levels regularly and make adjustments as needed to ensure optimal levels.

- Evaluate the effectiveness of optimization strategies and make adjustments as necessary.

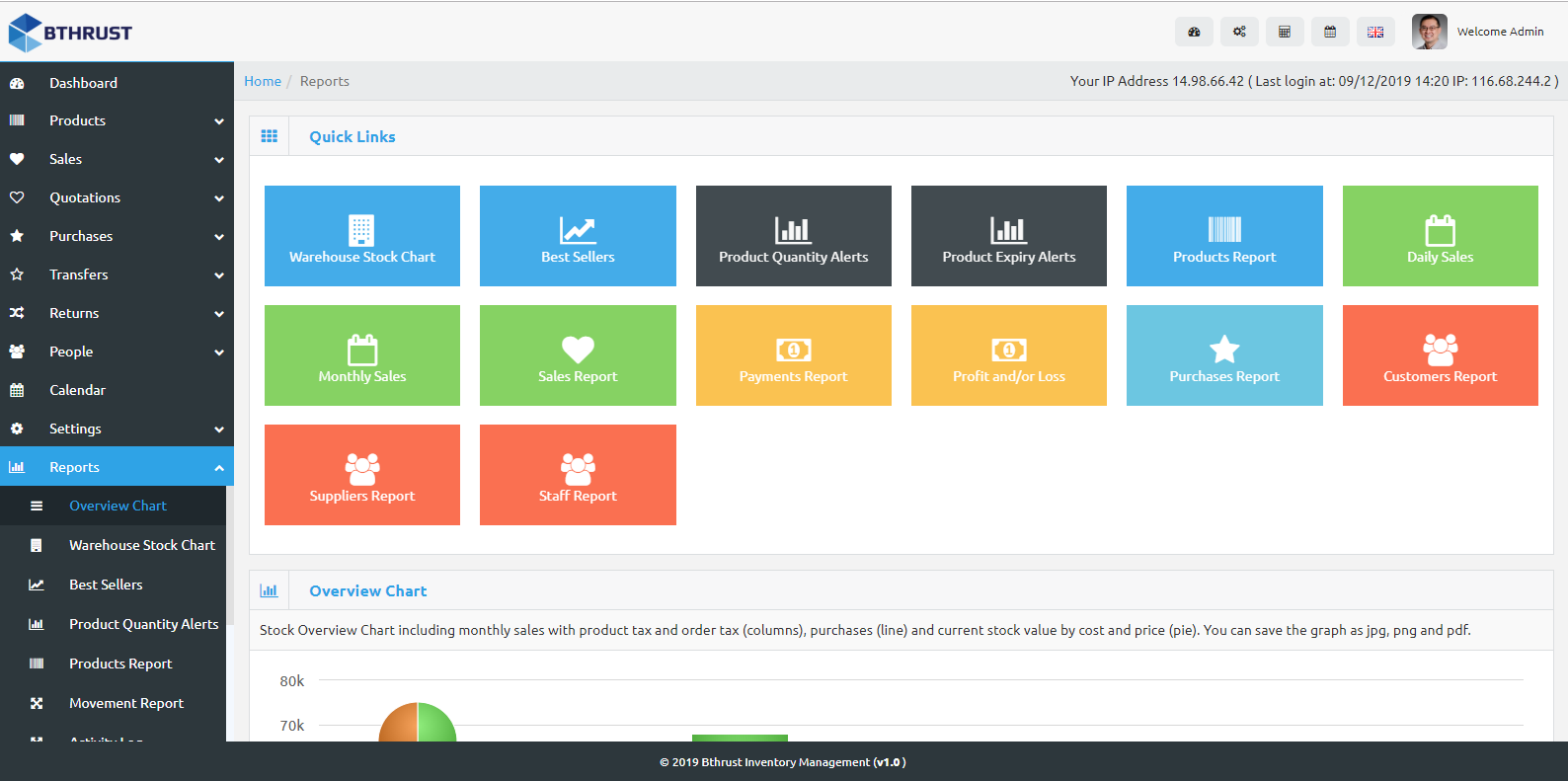

Integration with Other Business Systems

Integrating inventory programs with other business systems is crucial for efficient operations and data synchronization. It enables seamless communication and data exchange between different departments, eliminating manual processes and reducing errors.

Integration with Accounting Systems

Integrating inventory programs with accounting systems provides a comprehensive view of inventory-related financial transactions. It automates the recording of inventory purchases, adjustments, and sales, ensuring accurate and up-to-date financial records.

For instance, the integration with QuickBooks simplifies inventory management for small businesses. It allows automatic updates of inventory levels in the accounting system, eliminating the need for manual data entry and reducing the risk of errors.

Integration with CRM Systems

Integrating inventory programs with CRM systems provides real-time visibility into inventory availability for sales teams. It enables sales representatives to check stock levels, track orders, and manage customer inquiries efficiently.

For example, integrating with Salesforce allows sales teams to access inventory data within the CRM platform. This empowers them to make informed decisions, provide accurate delivery estimates, and improve customer satisfaction.

Integration with Supply Chain Management Systems

Integrating inventory programs with supply chain management systems streamlines the flow of goods from suppliers to customers. It automates order processing, inventory replenishment, and logistics management, reducing lead times and improving efficiency.

For instance, integrating with SAP ERP enables businesses to manage their entire supply chain, including inventory levels, supplier relationships, and transportation. This integration provides a centralized platform for optimizing inventory management and reducing operational costs.

Trends and Future of Inventory Management

Inventory management is undergoing a transformation, driven by technological advancements and changing business practices. Emerging trends are reshaping the way businesses manage their inventory, leading to increased efficiency, accuracy, and optimization.

Impact of Technology, Automation, and Data Analytics

Technology is playing a pivotal role in revolutionizing inventory management. Automation tools streamline tasks such as order fulfillment, stock replenishment, and demand forecasting. Data analytics provides valuable insights into inventory patterns, enabling businesses to make informed decisions and optimize their inventory levels.

Future of Inventory Management Practices

The future of inventory management lies in the integration of advanced technologies, such as artificial intelligence (AI) and machine learning (ML). AI algorithms can automate inventory management processes, predict demand more accurately, and optimize stock levels in real-time. ML models can analyze vast amounts of data to identify trends, patterns, and anomalies, leading to better inventory planning and decision-making.

Last Point

The future of inventory management holds exciting prospects, with advancements in technology and automation set to revolutionize the way businesses manage their inventory. By embracing these advancements, businesses can unlock new levels of efficiency, accuracy, and customer satisfaction, solidifying their competitive edge in the dynamic global marketplace.

Question & Answer Hub

What are the key benefits of implementing business inventory programs?

Business inventory programs offer numerous benefits, including reduced costs, improved efficiency, enhanced customer satisfaction, streamlined operations, and better decision-making.

What types of inventory programs are available?

There are various types of inventory programs available, each with its own features and functionalities. Some common types include perpetual inventory systems, periodic inventory systems, and just-in-time inventory systems.

How can inventory optimization techniques help businesses?

Inventory optimization techniques, such as safety stock management, reorder point calculation, and inventory forecasting, enable businesses to maintain optimal inventory levels, minimizing waste and maximizing profitability.