Business inventory management system, the backbone of inventory management, is a comprehensive solution that empowers businesses to streamline their inventory operations, enhance efficiency, and maximize profitability. From retail stores to manufacturing plants, industries across the board rely on inventory management systems to gain real-time visibility into their stock levels, optimize order fulfillment, and make informed decisions that drive growth.

With its robust set of features, a business inventory management system empowers businesses to track stock levels with precision, process orders seamlessly, and generate insightful reports that aid in strategic planning. By leveraging these capabilities, businesses can maintain optimal inventory levels, reduce waste, and enhance customer satisfaction.

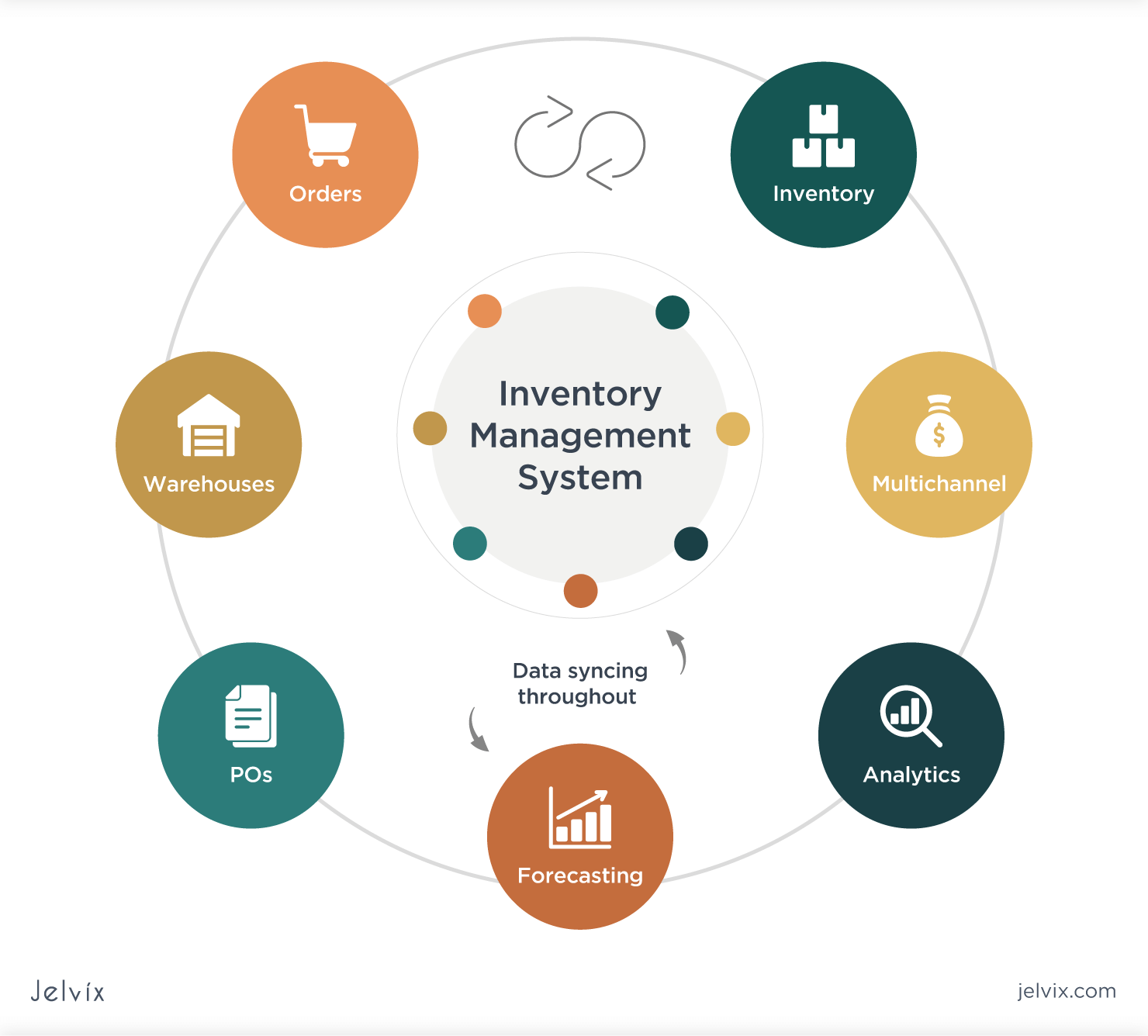

Inventory Management System Overview

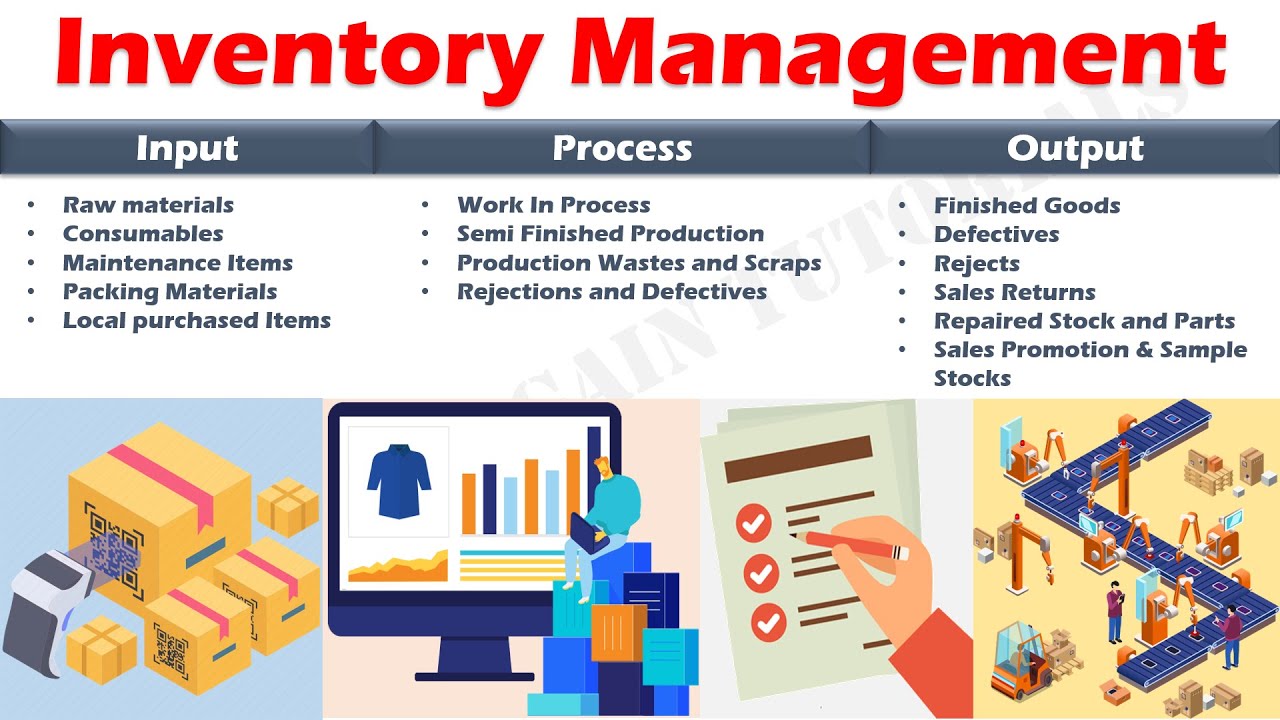

An inventory management system is a software application that helps businesses track and manage their inventory levels. It can be used to track inventory in multiple locations, manage inventory costs, and generate reports on inventory levels and trends.

Inventory management systems can provide a number of benefits to businesses, including:

- Improved inventory accuracy

- Reduced inventory costs

- Increased sales

- Improved customer service

Businesses in a wide range of industries rely on inventory management systems, including:

- Retail

- Manufacturing

- Wholesale

- Distribution

Key Features of an Inventory Management System

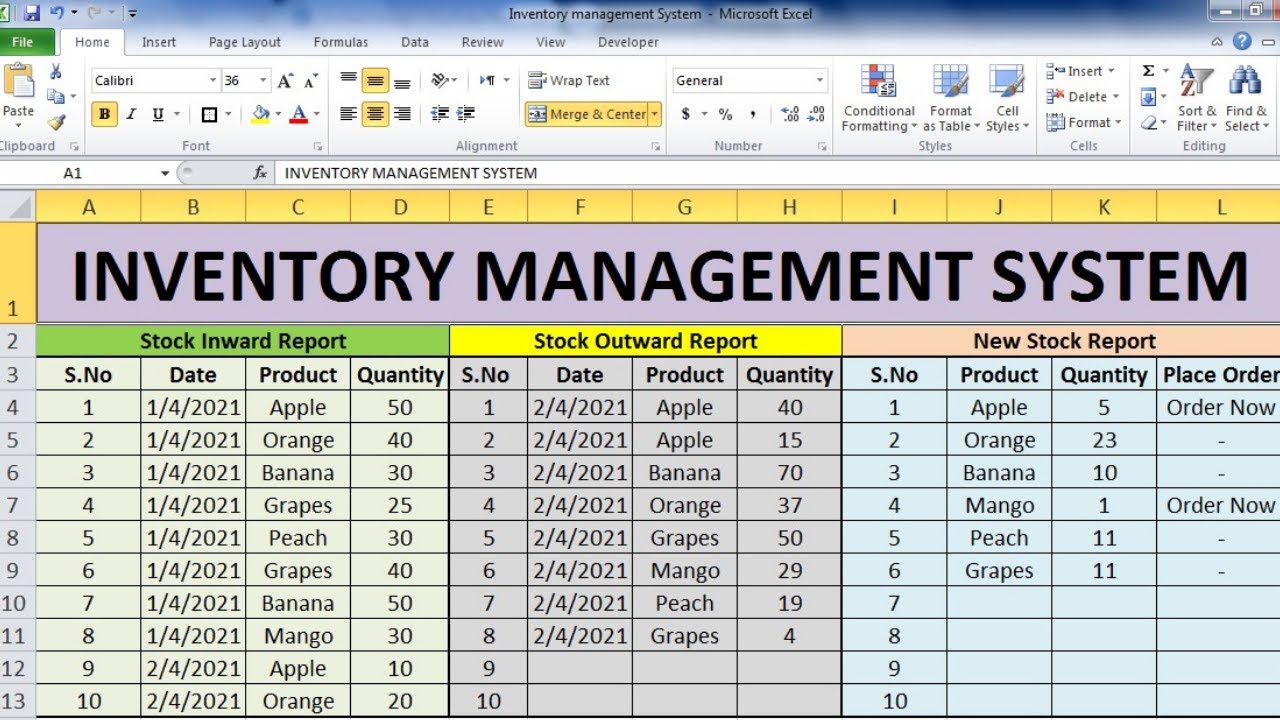

Inventory management systems are software solutions that help businesses track, manage, and optimize their inventory levels. They offer a range of core functionalities that streamline inventory operations and provide valuable insights for better decision-making.

One of the key features of an inventory management system is stock tracking. This allows businesses to monitor the quantity and location of their inventory items in real-time. By accurately tracking stock levels, businesses can prevent overstocking and understocking, ensuring they always have the right amount of inventory to meet customer demand.

Order Processing

Inventory management systems also streamline order processing. They allow businesses to quickly and efficiently process orders, update inventory levels, and generate shipping documents. This helps businesses fulfill orders faster and improve customer satisfaction.

Reporting

Reporting is another important feature of inventory management systems. They provide businesses with detailed reports on inventory levels, sales trends, and other key metrics. These reports help businesses identify areas for improvement, make informed decisions, and optimize their inventory management strategies.

Benefits of Using an Inventory Management System: Business Inventory Management System

Implementing an inventory management system brings a plethora of benefits to businesses. It enhances inventory accuracy, leading to reduced costs and improved customer satisfaction.

Improved Inventory Accuracy

An inventory management system provides real-time visibility into inventory levels, eliminating manual errors and discrepancies. This accuracy ensures that businesses have the right products, in the right quantities, at the right time.

For example, Amazon utilizes an advanced inventory management system that tracks every item in its vast warehouses. This system has significantly improved inventory accuracy, reducing the number of out-of-stock situations and increasing customer satisfaction.

Reduced Costs, Business inventory management system

By optimizing inventory levels and reducing waste, businesses can save significant costs. An inventory management system helps businesses avoid overstocking, which leads to reduced storage costs, insurance premiums, and spoilage. It also helps prevent understocking, which can result in lost sales and customer dissatisfaction.

Walmart’s inventory management system has helped the company reduce inventory holding costs by 15%, resulting in millions of dollars in savings.

Enhanced Customer Satisfaction

Accurate and efficient inventory management directly impacts customer satisfaction. When businesses have the right products in stock, they can fulfill orders promptly and avoid disappointing customers with out-of-stock situations. This leads to increased customer loyalty and repeat business.

Apple’s inventory management system ensures that popular products are always available in stores and online. This has contributed to Apple’s exceptional customer satisfaction ratings and its position as one of the most valuable companies in the world.

Implementation and Integration

Implementing an inventory management system involves several crucial steps to ensure seamless integration and successful utilization.

The initial phase comprises data collection, where information regarding inventory items, their attributes, storage locations, and other relevant details is gathered and organized. This data serves as the foundation for the system’s functionality.

System Configuration

Subsequently, the system is configured based on the collected data and specific business requirements. This includes defining inventory parameters, setting up user roles and permissions, and customizing workflows to align with the organization’s processes.

Training

Comprehensive training is essential to empower users with the knowledge and skills necessary to operate the inventory management system effectively. This training covers system navigation, data entry procedures, and best practices for inventory management.

Integration

To maximize the value of an inventory management system, it should be integrated with other business systems, such as ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management) systems.

Integration with ERP systems enables real-time synchronization of inventory data, eliminating the risk of discrepancies between systems. This ensures that inventory levels, costs, and other critical information are always up-to-date.

Integrating with CRM systems provides a comprehensive view of customer interactions, sales orders, and inventory availability. This enables businesses to align their inventory management strategies with customer demand, improving order fulfillment and customer satisfaction.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to optimize operations, reduce costs, and enhance customer satisfaction. Implementing best practices can help businesses streamline their inventory processes and achieve better outcomes.

Some key best practices for inventory management include:

Setting Safety Stock Levels

Maintaining appropriate safety stock levels is essential to prevent stockouts and ensure uninterrupted operations. Safety stock acts as a buffer against unexpected demand fluctuations or supply chain disruptions.

To determine optimal safety stock levels, businesses should consider factors such as:

- Average demand

- Lead time for replenishment

- Expected demand variability

- Service level requirements

Conducting Regular Inventory Audits

Regular inventory audits are crucial to ensure accuracy and minimize discrepancies between physical inventory and records. Audits help identify and rectify errors, prevent shrinkage, and improve overall inventory management.

Businesses should establish a regular schedule for inventory audits, depending on the size and complexity of their inventory.

Utilizing Inventory Forecasting Techniques

Inventory forecasting techniques help businesses predict future demand and optimize inventory levels accordingly. By leveraging historical data, statistical models, and market trends, businesses can make informed decisions about inventory replenishment and avoid overstocking or understocking.

Examples of companies that have successfully implemented these best practices include:

- Amazon:Utilizes advanced inventory forecasting algorithms and maintains strategic safety stock levels to ensure customer satisfaction and minimize stockouts.

- Walmart:Implements a robust inventory management system that tracks inventory in real-time and enables efficient replenishment based on demand patterns.

- Toyota:Adopts the “just-in-time” inventory approach, minimizing inventory levels and relying on timely supplier deliveries to reduce waste and improve efficiency.

Future Trends in Inventory Management

The future of inventory management is poised to be revolutionized by emerging technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). These advancements are transforming the way businesses track, manage, and optimize their inventory levels.

AI and ML

AI and ML algorithms can analyze vast amounts of data to identify patterns, predict demand, and optimize inventory levels. By leveraging these technologies, businesses can automate inventory management tasks, reduce human error, and make data-driven decisions.

IoT

IoT devices, such as sensors and RFID tags, provide real-time visibility into inventory levels. This data can be integrated with inventory management systems to track inventory movement, monitor stock levels, and trigger automated reordering when necessary.

Final Conclusion

In conclusion, a business inventory management system is an indispensable tool for businesses seeking to optimize their inventory management practices. By implementing a robust system, businesses can streamline operations, reduce costs, improve customer satisfaction, and gain a competitive edge in today’s dynamic market landscape.

FAQ Explained

What are the key benefits of using a business inventory management system?

Improved inventory accuracy, reduced costs, enhanced customer satisfaction, streamlined operations, and data-driven decision-making.

What types of businesses can benefit from a business inventory management system?

Retail stores, manufacturing plants, warehouses, e-commerce businesses, and any organization that manages physical inventory.

How does a business inventory management system integrate with other business systems?

Through APIs and data exchange protocols, inventory management systems can seamlessly integrate with ERP, CRM, and other business applications.